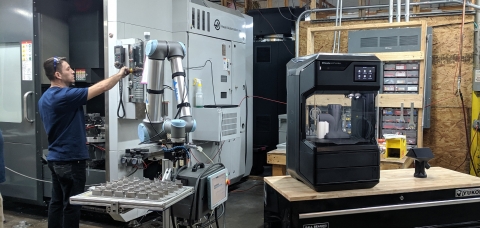

All Axis Robotics: Printing end of arm effectors

ABOUT THE PROJECT

This custom dual-grit robot sander attachment was designed and manufactured in-house by All Axis engineers in under two weeks using a MakerBot METHOD X 3D printer with strong and durable real ABS material. The robot sander automates the time-consuming manual aluminum sanding operation, helping a machine shop to run more efficiently by freeing up personnel for other tasks. It features two sides with different grid sand pads as well as a connection for a vacuum to remove debris.

KEY TAKEAWAYS

- Tooling for robotic arms requires tight tolerances close to ±0.007 in (± 0.2 mm) and hole cylindricity for optimal fit and function.

- Large overhangs, carve-outs, and other complex part features are near-impossible to machine, requiringStratasys® SR-30 soluble support material.

- All Axis was able to create their part using production-grades

More Information:

Manufacturer: