Stand Up Counterbalanced Lift Truck Personal Simulator

To maximize storage density, warehouses and distribution centers increasingly adopt narrow aisles that require specialized counterbalanced lift trucks with “stand-up” functionality. These lift trucks, sometimes called "dock stockers," are designed to operate effectively at loading docks and within narrow aisle racking systems.

Simlog offers advanced simulation solutions for operator training, including:

- Forklift Personal Simulator: Train operators to handle sit-down counterbalanced lift trucks.

- Reach Lift Truck Personal Simulator: Prepare operators to manage narrow aisle stand-up lift trucks with extendable and retractable forks.

Now, Simlog’s Stand Up Counterbalanced Lift Truck Personal Simulator takes training to the next level. It places users at the controls of a typical stand-up (narrow aisle) counterbalanced lift truck, tailored to meet OSHA Class 2 operator training program requirements.

Key Features

- Realistic Simulation: Experience photo-realistic graphics and best-in-class simulation physics.

- Superior Instructional Design: Deliver unmatched operator training support.

- Customizable Settings: Configure software to replicate the controls and steering behaviors of the most common stand-up counterbalanced lift trucks.

- Flexible Display Options:

- Use a single display for space-constrained setups.

- Opt for three displays positioned to replicate "side stance" views, essential for looking backward, sideways, and forward during operation.

- Off-the-Shelf Convenience:

- Use your own PC or select Simlog’s PC bundle, preloaded with licensed software and ready to go.

This innovative solution makes high-quality training accessible with just one off-the-shelf computer and an easy-to-set-up system. Simlog’s Stand Up Counterbalanced Lift Truck Personal Simulator ensures a seamless blend of realism, adaptability, and performance for your operator training needs.

Simulator Controls

Simlog’s advanced simulation solutions bring realism and versatility to operator training with Industrial Controls, Replica Controls, and multi-purpose functionality

Simlog's USB-ready Industrial Controls deliver a premium simulation experience, featuring authentic operator controls and a portable, fully assembled industrial console designed for stand-up use. These controls faithfully replicate the look and feel of real stand-up counterbalanced lift trucks, providing an ideal training solution.

Key Features

- OEM Control Handle: Three handle options compatible with seven major brands.

- Steering Tiller: Realistic reproduction of stand-up lift truck steering controls.

- Foot Brake Pedal: Provides accurate braking feedback.

- Viewpoint Control:

- Two pushbuttons for switching perspectives.

- Mini-joystick to pan and tilt views during simulation.

- Emergency Power Disconnect: For added safety.

- Front Panel Key Lock: Restricts access to the internal PC.

Setup Options

- Single Display: Positioned in front for forward-view training.

- Triple Display: Horizontal or vertical alignment to simulate "side stance" views—left, front, and right perspectives for realistic operator positioning.

Specifications

- Console Dimensions:

- 19.5” D x 39” W x 46” H

- Weight: 110 lbs.

- Shipping:

- Dimensions: 24” x 44” x 54”

- Weight: ~150 lbs.

- One unit per skid, not stackable.

- Power Requirements: 120 VAC/60 Hz or 220-240 VAC/50 Hz

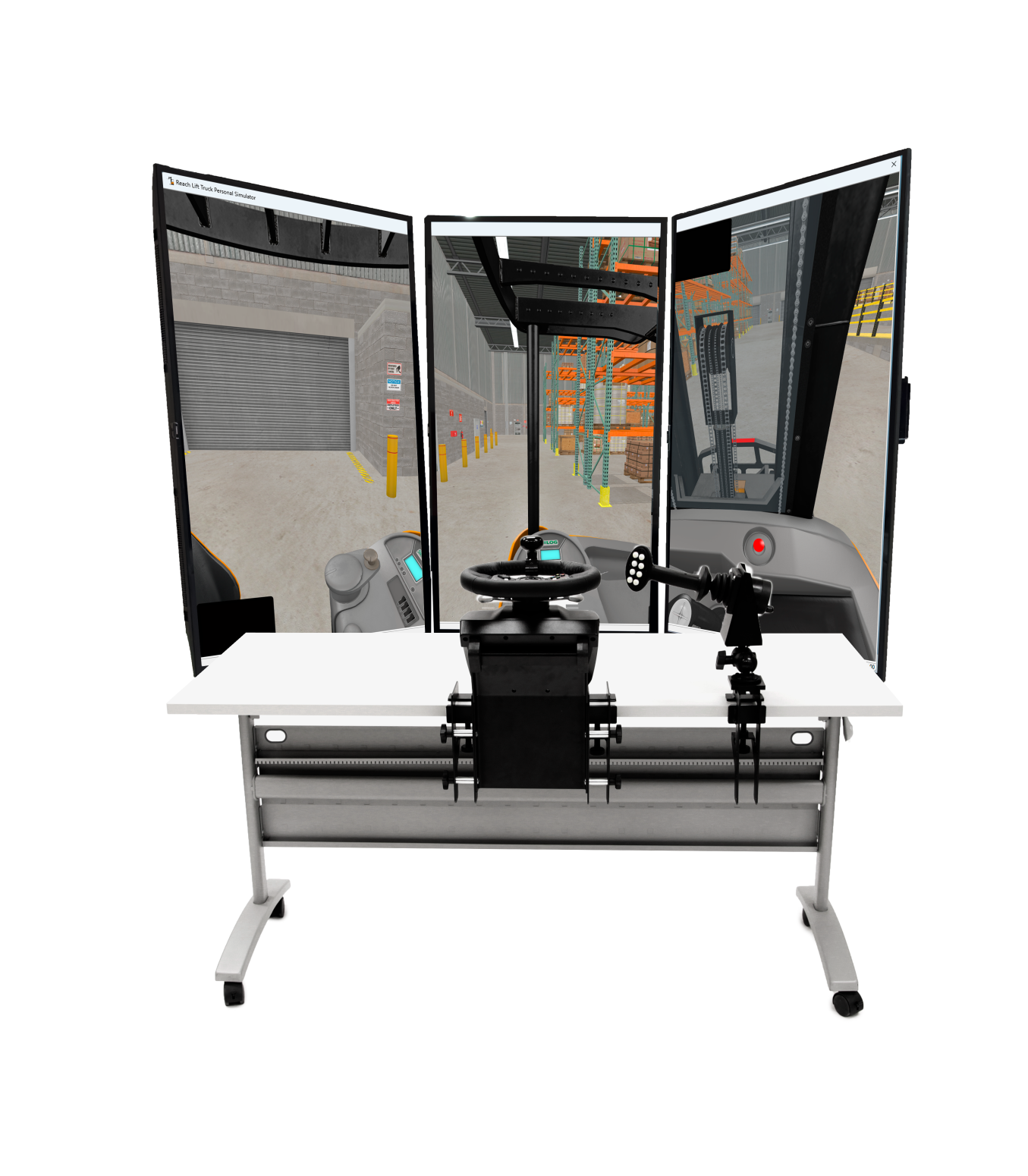

Simlog’s Replica Controls for the Stand Up Counterbalanced Lift Truck Personal Simulator are designed for realistic, industrial-strength operator training. These USB-ready controls feature mounting brackets for standing use, replicating the experience of operating real stand-up equipment.

Key Features

- Left-Hand Control:

- Horizontally-positioned Logitech G920 steering wheel with a steering knob for precise, single-hand control.

- The steering wheel is widely available in retail and online stores.

- Right-Hand Control:

- USB-ready joystick for proportional forward/reverse travel control.

- Optional horizontal or vertical joystick positioning to mimic real equipment configurations.

- Pushbuttons for tilt, side shift, and viewpoint adjustments during simulations.

- Safety Note: The Replica Controls do not include a pedal for emergency stops, as this function is for safety and not operational training.

Setup Options

- Single Display: Positioned in front for forward-view training.

- Triple Display: Left, front, and right displays to simulate side stance views for backward, side, and forward perspectives.

Custom Travel Case

Simlog offers a made-to-measure Custom Travel Case to simplify transportation of Replica Controls.

- Includes slots for the steering wheel, joystick, and mounting brackets.

- Space for a laptop, cables, and documentation.

- Features a pull-out handle, wheels, and stackable design for convenience.

Specifications

- Travel Case Dimensions: 30″ x 24″ x 19″

- Weight: Approximately 50 lbs. empty, up to 100 lbs. when full.

This solution provides a portable and customizable simulation experience, tailored to meet diverse operator training needs.

Stand-up reach lift trucks and stand-up counterbalanced lift trucks are commonly used in warehouses and distribution centers. Reach lift trucks excel indoors, navigating tall and narrow racking systems, while counterbalanced lift trucks are ideal for loading and unloading trailers and sea containers at the docks.

With Simlog, you can create a versatile Personal Simulator station to train operators on both types of lift trucks.

This setup allows you to use the same Simulation Manager, simulator controls, computer, displays, and speakers—offering a cost-effective and efficient solution for comprehensive operator training.

Software Description

Simlog’s Stand Up Counterbalanced Lift Truck simulation software offers extensive customization options to replicate real-world operator controls and steering behaviors. For instance, users can select between “Forward” (Front Directional) or “Reverse” (Rear Directional) steering conventions. Safety features include “halo lights,” which project red perimeter lines on the factory floor and a blue safety circle behind the lift truck.

The software includes 14 Simulation Modules to progressively train operators, starting with basic controls and advancing to complex tasks. Modules include tasks like slalom driving, ramp navigation, and loading/unloading trailers and containers, as well as work with various pallet rack systems.

- Controls Familiarization

- Slalom 1 – Forward

- Slalom 2 – Reverse

- Ramp Driving

- Flatbed Truck

- Loading a Shipping Container

- Unloading a Shipping Container

- Loading a Dry Van Trailer 1 – Single Loads

- Unloading a Dry Van Trailer 1 – Single Loads

- Loading a Dry Van Trailer 2 – Stacked Loads

- Unloading a Dry Van Trailer 2 – Stacked Loads

- Selective Pallet Racks 1 – Standard Aisles

- Selective Pallet Racks 2 – Narrow Aisles

- Drive-In / Drive-Through Racks

The software makes collisions visible during and after trials to enhance safety training. This allows trainees to review collisions in detail during "after-action reviews" and learn to avoid repeated mistakes. For example, damage to pallet racks from collisions is clearly displayed to reinforce correct operating techniques.

The simulation provides dynamic viewpoints to enhance training. Inside the cabin, displays replicate "side stance" views for backward, side, and forward perspectives. For additional guidance, external viewpoints can be activated using simulator buttons, keyboard keys, or the PC’s mouse.

The software tracks 58 unique Key Performance Indicators (KPIs) to measure both efficiency and safety. Diagnostic feedback includes execution time, driving speeds, load positioning accuracy, and collision counts. Errors are categorized as follows:

- Procedure Errors: Driving out of bounds or operating incorrectly.

- Fatal Errors: Critical safety violations like severe collisions or overturn risks that stop the simulation immediately.

This comprehensive feedback system helps trainees improve precision, safety, and operational skills.