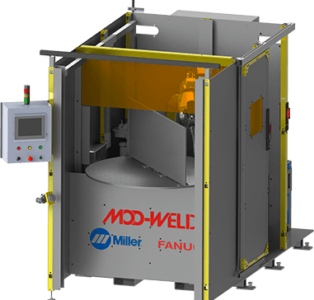

MOD-WELD

Allow your welders to double their throughput with a pre-engineered robot welding system. Both the MAC series, designed with a FANUC CRX Cobot, and the MATE series, designed with a FANUC ARC Mate robot, give endless opportunities for quick setup and ease of use. The MOD-WELD is made for quality and productivity, whether low/high mix or low/high-volume production.

Features

- FANUC Robot / Miller Power Source / Rockwell Controls Integrated by APT Manufacturing

- Load/Unload directly into the weld cell

- Locating holes for Fixtures to be removed and set back up in the same location

- Ease of setting up

- Easy maintenance and cleanliness

- Side access door for entering a safe environment

- Small footprint

- Recipe Management with room for up to 100 recipes

MOD-WELD Cobot

The MOD-WELD is designed and manufactured around FANUC’s new CRX-10iA and CRX-10iA/L industrial collaborative robots. The CRX models come from a long line of reliable FANUC products that are extremely easy to set up, program, and operate – even if it’s your first robot. View Cobot Modular Table Cart.

Extended Table Space Options

Add up to 4 side carts in different configurations for customizing your workspace.

Table Options

Fixed Table

The fixed table allows the operator to load the parts directly into their fixture as the robot waits in a safe position for the safety door to close before welding.

The Aux Wide option adds a FANUC Aux Axis to rotate the fixture into the robot for ease of welding on the backside.

Tilt/Rotary Table

Allows the operator to load/unload the product outside the weld cell, then the rotary table will bring the product into the cell for welding.

When the robot completes the welds on one side, it will rotate the table and begin welding on the other.

Operator Interface

Our standard MOD-WELD systems use APT’s efficient and easy-to-use operator interface. Learn More.

Features

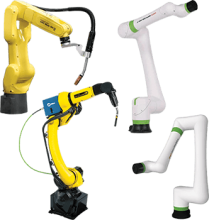

Robot Options

- FANUC ARC Mate 50iD

- FANUC ARC Mate 100iD

- FANUC CRX-10iA for ARC

- FANUC CRX-10iA/L for ARC

Miller Auto-Continuum™

Next-generation automation welding solution delivers advanced arc performance to improve throughput and weld quality.

Features

- Operator Friendly Rockwell HMI Interface

- 16 inputs and 16 outputs for sensors and clamps

- Recipe Management System for program storage

- Easy to add new programs

More Information

Visit APT Manufacturing for more information.