Plate-Type Heat Exchanger Model

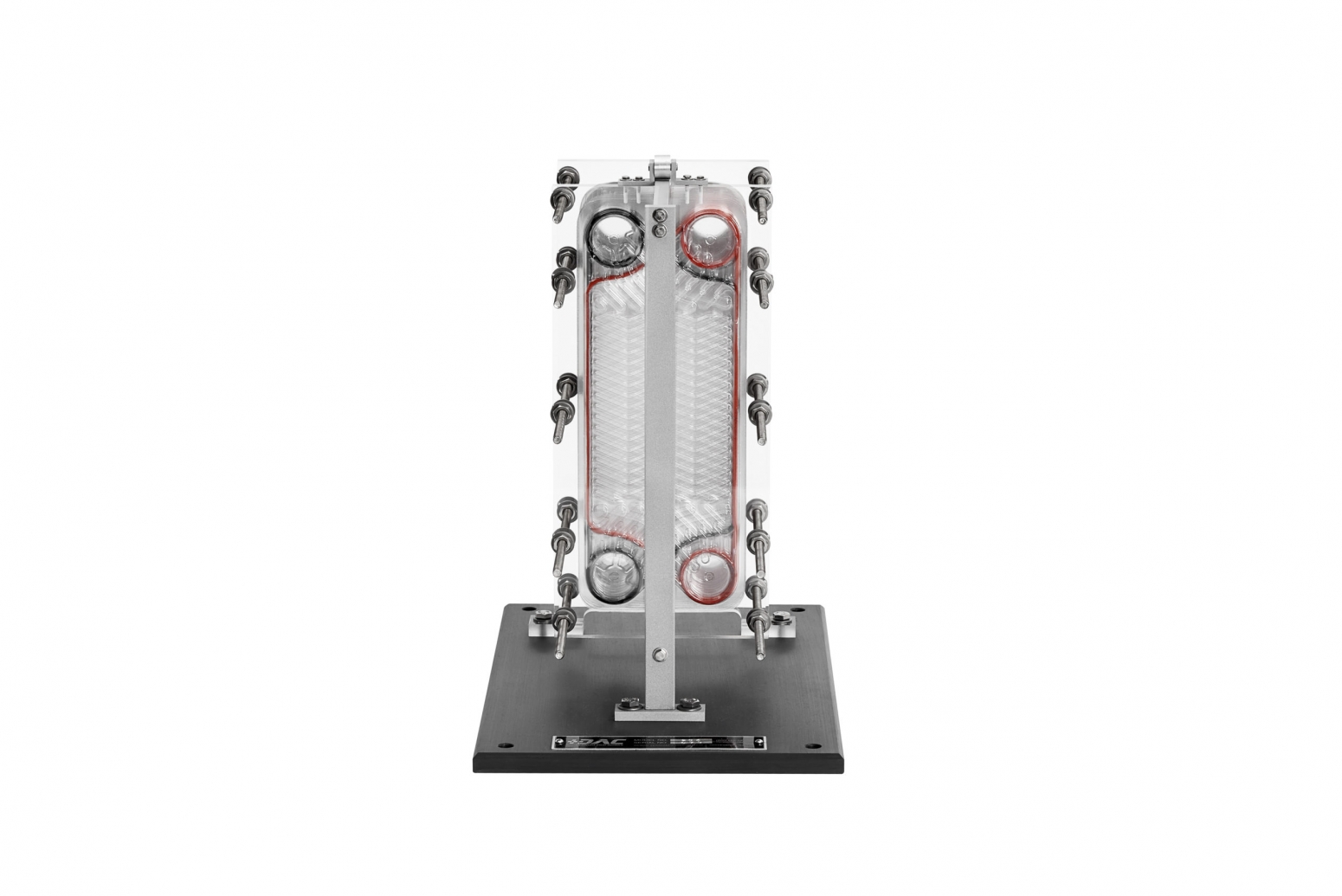

DAC Worldwide’s Plate-Type Heat Exchanger Model (284) depicts a highly-detailed scale model of a common plate-type heat exchanger in a technically-accurate, professionally-crafted design. Based on a common make and model of a heat exchanger, the product is a complete to-scale replication of typical plate-type heat exchangers found in industry.

The model features clear acrylic components, chevron plates cutaways, color coding, and realistic detail, which combine to make this a useful tool in both operations and maintenance training of industrial heat exchangers. The model can also be completely disassembled, and incorporates cut away areas illustrating the flow path.

This realistic mechanical model includes acrylic flanges and nozzles, four (4) vacuum-formed chevron plates, a detailed chevron plate mass, and many more industrial-grade component replicas. Learners will use these replicas to study topics such as the purpose of heat exchangers, the difference between co-current and counter-current flow arrangements, different exchanger types, and more.

Enhance Learning Using DAC Worldwide’s Technically-Accurate Models

DAC Worldwide’s hands-on models take learning to the next level, offering both visual and physical learning styles to appeal to a variety of learners.

This model features clear acrylic stationary ends, flanges, and nozzles, which allows complete visibility of internal components. In addition, seals of detailed plates are color-coded for visibility, and to show flow path. To ensure an ideal training experience, the model also includes a durable PVC base, with provisions for tabletop mounting. All of the construction throughout the model is to-scale, and the perfect 3-dimensional solution for engineering study, promotion, and training.

Expand Training with Additional Mechanical Models

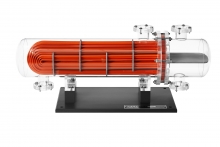

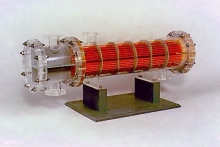

The Plate-Type Heat Exchanger Model is only one of DAC Worldwide’s expansive mechanical training models, which also includes a U-Tube Heat Exchanger Model (#285), Multi-Pass Heat Exchanger Models (#286 & #287), a Vertical Thermosyphon Reboiler Heat Exchanger Model (#289), and many more!

Features & Specifications

- Exact "to-scale" construction throughout

- Clear acrylic stationary ends, flanges, and nozzles

- Four (4) vacuum-formed, corrugated chevron plates of two varieties

- Cutaway of two (2) chevron plates, allowing view of flow path

- Detailed chevron plate mass

- Representative color-coding of seals of detailed plates for visibility and to show flow path

- Opaque representative seals

- Stainless steel hardware

- Anodized aluminum chevron plate support structure

- Durable PVC baseplate with provision for tabletop mounting, and mounting on related display rack structures

- Packaging for shipment via motor freight

- Product Dimensions (L x W x H)18in. x 9in. x 16in.

- Weight 12 lbs.