Improve efficiency with clear, accurate guides and models.

Perform faster, more accurate procedures with customized cutting guides and surgical models made with Somos® BioClear. Not only will this decrease the recovery time for patients, it can also lessen the chances of repeat procedures.

Somos® BioClear fulfills the requirements for non-implantable limited body contact (<24hr) medical and dental applications. Somos® BioClear has passed stringent ISO 10993-5 Cytotoxicity, ISO 10993-10 Irritation & Sensitization, and USP Class VI testing, after following the cleaning procedure as described in the Somos® BioClear user guide.

Parts produced from Somos® BioClear are accurate, clear and have ABS-like mechanical properties and a good combination of strength and toughness. The material is resistant to moisture and many common solvents and chemicals.

Fast and easy production of quality hollow composite tooling parts, that are easy to remove after the autoclave process.

While basic composite shapes with constant cross sections are easily manufactured using traditional composite manufacturing techniques, complex parts with hollow interiors present a unique challenge. Additive manufacturing has fundamentally changed the process. High-temperature, cost-effective tools can now be produced in days, compared to the weeks or even months required for traditional tooling, and provides a cost-effective solution even for small series production.

Somos® DMX SL-100, a durable and tough stereolithography (SL) resin, is an efficient and cost-effective solution that produces very accurate parts with a superb surface finish and high feature detail, promoting greater design freedom for composite applications.

Somos® DMX SL-100 withstands the high temperatures utilized in the autoclave process for composites manufacturing maintaining its flexural strength, elongation and tear resistance. These unique properties allow, at a certain temperature, for mandrels to be removed from complex and convoluted geometries through a “dry removal” process which is unique for a solid mandrel. Other soluble wash out cores need submerging in caustic which can affect the composite part. No other material in the industry is as easily and best removed after the autoclave process, facilitating the more efficient production of complex, hollow composite parts.

This method of using additive manufacturing to produce sacrificial tooling is straightforward and enables multiple iterations to be implemented quicker by the user.

In partnership with Covestro Additive Manufacturing (formerly DSM) and its Somos® resins, the Neo 3D printers can run the most technically advanced stereolithography materials.

A stereolithography material engineered to create flawless investment castings patterns.

Through continuous interaction with our customers, pattern makers and foundries, our team developed Somos® Element for producing investment casting patterns.

Somos® Element is an antimony-free stereolithography material specifically designed to improve the repeatability and quality of 3D printed casting patterns. Patterns created with Somos® Element leave trace amounts of lightweight, easily-removable ash residue after burnout and have better green strength, so there’s no worry of breakage during handling, while being dimensionally stable during storage. Any residue left behind is easily removed, leaving a perfectly clean void in the ceramic mold. This translates into lower mold prep times and lower rates of rework, saving customers time and money.

Key Benefits

- Trace amounts of ash that are lightweight and easily removed

- Suitable for high-end alloy castings

- Rapid draining

- Produces accurate, repeatable parts regardless of size

A resin offering durability and fast processing times.

Somos® EvoLVe 128 is a durable stereolithography material that procudes accurate, high-detailed parts and has been designed for easy finishing. It has a look and feel almost indistinguishable from finished traditional thermoplastics, making it excellent for building parts and prototypes for functional testing applications – resulting in time, money, and material savings during product development. Somos® EvoLVe is an excellent material for industries such as aerospace, automotive, medical, consumer products, and electronics.

Key Benefits

- Easy to clean & finish

- High strength & durability

- Accurate & dimensionally stable

- High detail

A universal stereolithography material designed to produce accurate, detailed parts across various applications.

Somos® GP Plus 14122 sets the standard for 3D printing prototypes. It is easily integrated in production cycles to test designs ensuring proper functionality of parts before they are launched into full production – providing customers the opportunity to get to market quickly. Parts produced with Somos® GP Plus 14122 are durable, accurate and moisture-resistant. This material is ideal for functional prototypes, concept models, and low-volume production parts.

Key Benefits

- Extremely accurate

- Excellent humidity resistance

- Very durable

Additive manufacturing, and more specifically stereolithography (SL), has enabled a faster route to market for footwear while reducing development costs and aiding the development of more complex shoe designs. With Somos® Momentum, Stratasys provides a compelling solution combining rich feature detail and dimensional stability with more efficient printing outcomes available without compromising surface quality and dimensional accuracy.

Footwear manufacturers face a multitude of challenges, from developing durable solutions to managing design and the range of sizes required. They continue to seek more effective means to develop new designs to meet increasingly diverse customer needs, while also striving to quicken the pace of design and innovation. Additive manufacturing for footwear tooling has played a key role, and the inherent design flexibility, feature detail, and surface quality offered by SL has led this technology into the mainstream. Footwear manufacturers continue to push for faster design iteration, shorter route to market and more cost- and time-efficient approaches.

Stratasys collaborated with key footwear manufacturers to develop an additive manufacturing material that addresses the specific needs for footwear tooling. Somos® Momentum offers higher part accuracy, quality and fine feature detail. The outstanding accuracy of the resin allows the forming of sharp features, which in turn enables the creation of detailed soles not only in initial design but also translated into the aluminum mold. In addition, the pink color of the material makes it easy to discern key features in the design and to inspect the parts for surface defects. Taking this technology a step further, direct printing of the sole will omit the need for detailing or texturing, speeding up the traditional tooling process up to 60%, enabling a cost reduction up to 30%.

Pages

-

L3 Harris' TranSim revolutionizes CDL training with immersive, realistic simulations. From city driving to hazardous conditions, it prepares drivers like never before, ensuring safety and competence in a controlled environment. Boosting confidence, reducing risks, and enhancing skills – TranSim sets the standard in commercial driver training.

-

Item Number:295-723DAC Worldwide's Treater Dump Valve Cutaway (295-723) is a sectioned industrial specialty oilfield valve for training in the operation, construction, and maintenance of on-off type dump valves.

-

The primary goal of this course is to teach workers safe procedures for working in and around a trench environment on a construction site. Hard Hat VR's Trenching and Excavation Simulation is ideal for future employees or supervisors who will work in or around trenches on construction sites.

-

Item Number:CO3221-7DTo prepare students for electrification of the powertrain in commercial vehicles, the renowned HV training system for passenger cars from Lucas-Nülle has been modified and adapted. The special learning concept of the training system, which combines theoretical and practical content in a target group-oriented manner, enables flexible on-site implementation that is taking regional, operational, and industry-specific features into account.

-

Item Number:CO3221-7FThis training system from the TruckTrain series focuses on the topic of "Smart Farming 4.0" based on the ISO bus. Special attention is paid to the function of "Precision Farming with Section Control", which is implemented in the hardware in a practical and interactive way.

-

A compact 2-axis CNC Lathe with totally enclosed high-visibility interlocking guard, suitable for all levels of education and training. Programmable spindle speeds and feedrates make the Turn 270 PRO ideal for cutting a range of resistant materials such as wax, plastic, acrylic, free cutting alloys, aluminum and steel.

-

Learn about the Turn 370 Pro CNC Lathe, a high-capacity 2-axis machine perfect for educational and training programs requiring precision and durability.

-

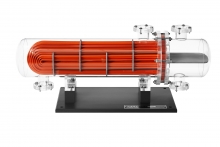

Item Number:285DAC Worldwide’s U-Tube Heat Exchanger Training Model (285) depicts a highly-detailed scale model of a common u-tube heat exchanger in a technically-accurate, professionally-crafted design. Based on a common make and model of a heat exchanger that reflects design standards established by the Tubular Exchanger Manufacturers Association (TEMA) and the ASME.

-

Item Number:CPK-UAM2-001Immerse your students in STEM with the thrill of UAV (Unmanned Aerial Vehicle) competitions. The kit introduces students to drone building and programming, with a focus on the classroom, community, statewide and national competitions. It includes a UAV frame, replacement parts, and a full library of sample programs to quickly get started. This fun, team-based setting inspires students to pursue STEM-based careers.

-

Item Number:MCK-DRGY-001The MINDS-i Drone Gimbal Rig gives you the ability to pilot the MINDS-i UAV in a safe and controlled environment. The preassembled rig allows you to introduce flight controls and best practices to anyone, regardless of skill level or age. With the Gimbal Rig’s 3-Axis system, you have the full-motion capabilities of the UAV at your fingertips. The MINDS-i Gimbal Rig is an excellent fit in a classroom, trade show, or convention.