What is LIFT? One of only a handful of Manufacturing USA Institutes across the country, LIFT is a nonprofit, public-private partnership between industry, academia, and government that supports the nation’s economy and enhances its national security by accelerating innovative advanced manufacturing technology and talent development.

In this video, STEM Talent Program Manager Bernie Simms, Learning Lab Manager Jihad Mims, and Learning Lab/Robotics Instructor Isaac Vanover discuss LIFT’s unique mission to research and develop innovative lightweight materials that advance the nation’s military defense and manufacturing capabilities.

According to Mims, “We also realized that there’s a very large skills gap. Over 2.5 million jobs within manufacturing were going unfilled, so to bridge that gap, we also wanted to make sure that education and workforce development was implemented in LIFT’s atmosphere. ”

That’s why you’ll find a wide variety of Amatrol training systems and eLearning curriculum in the LIFT Learning Lab. Amatrol also partnered with LIFT to develop the IGNITE: Mastering Manufacturing high school career and technical education program.

A fully automated cartoner for pouches, featuring robotic collation and loading, was engineered by FANUC’s Authorized System Integrator.

System Operation

Pouches emerge from the customer's pouch form-fill-seal (FFS) machine in a single-file fashion. The M-1iA robot strategically arranges alternate pouches, forming dual lanes at the cartoner infeed. Subsequently, two M-2iA robots precisely stage the pouches within collation fixtures, while an SR-6iA erects auto-bottom cartons and positions them on the carton conveyor. An M-10iD/12 robot expertly picks the staged pouches and deposits them into the erected cartons. The carton's top is then folded and tucked, and a collaborative CRX-10iA robot efficiently removes closed cartons, transferring them onto racks.

Key Advantages

- Capable of handling 100 pouches per minute

- Enhanced packaging speed

- Reduced footprint

ESS Technologies, Inc., a Pacteon Company, is a leading expert in comprehensive packaging line solutions, catering to industries such as pharmaceuticals, nutraceuticals, cosmetics, and consumer packaged goods. With a foundation dating back to 1993, ESS possesses extensive proficiency in designing, manufacturing, and integrating automatic cartoners, case packers, robotic palletizers, and TaskMate Robotic Systems®.

In this informative tutorial video, discover the ins and outs of navigating the touch screen interface on the CarTrain CO3221-6X. Whether you're a novice or an experienced user, this step-by-step guide will walk you through the various functions and features of the touch screen, allowing you to optimize your training experience. From accessing different modules to adjusting settings, learn how to harness the full potential of the touch screen interface with ease. Mastering this essential skill will enhance your proficiency in operating the CarTrain CO3221-6X and unlock a world of possibilities in automotive training.

Welcome to the Future of Additive Manufacturing with the H350 3D Printer

Step into the future of production with the H350 3D Printer, powered by groundbreaking SAF technology. Experience precision and consistency redefined in our latest video, showcasing the innovative features that set the H350 apart in high-volume manufacturing. Discover how SAF technology transforms the production landscape, offering unparalleled efficiency and accuracy. Ready to lead your business into a new era of additive manufacturing?

Unrivaled Precision and Repeatability

In final product production, precision, repeatability, and consistency are key to scaling into production volumes. The H350 3D printer, powered by SAF technology, achieves this for production-grade parts—not just across each print, but build after build and across different printers and locations. Customers can trust the process thanks to the foundation of SAF technology's unparalleled accuracy and repeatability.

Innovative SAF Technology

The foundation of SAF technology's unparalleled accuracy and repeatability lies in its unique time-temperature consistency across the bed and its best-in-class thermal closed-loop control. An important element of fusing particles together relies on temperature and time of fusion. SAF is unique in that the temperature and time for fusing particles are consistent at all points across the bed. To further reinforce consistency, SAF is equipped with the best-in-class thermal closed-loop control.

Advanced Thermal Control

At an impressive 300,000 pixels, SAF's high-resolution thermal camera offers up to 100 times higher pixel density than comparable print head-based powder bed fusion technologies. This remarkable level of detail allows for highly accurate temperature measurements during printing. The H350 features the innovative Vortex Bell, shielding the camera from any interference, ensuring uninterrupted vision and capturing every critical detail at a remarkable 30 frames per second.

Efficient Thermal Control

Precision isn't limited to just capturing data; it also leads to efficient thermal control. The H350's patented optimized heating system configuration is designed using state-of-the-art AI techniques. The heating system's infinite loop design and its unique mesh configuration optimize thermal control of the powder bed, resulting in enhanced efficiency and stability throughout the printing process.

Trust in the Process

Thanks to SAF's improved accuracy and consistency, customers can now trust in the process. Scale your production volumes with the H350 and SAF technology, leading your business into the future of additive manufacturing.

Discover the ultimate solution for hands-on learning with the FANUC 0i-MODEL F Plus Simulator. Designed specifically for educational purposes, this cutting-edge tool revolutionizes the way students engage with CNC technology. Compact, portable, and seamlessly integrated into any classroom, it empowers educators to inspire the engineers of tomorrow. Dive into limitless learning possibilities and prepare your students for success in advanced manufacturing. Explore the features and benefits of the FANUC 0i-MODEL F Plus Simulator below and revolutionize your teaching approach today!

As pioneers in tactical medical equipment and training, TacMed Solutions is dedicated to providing cutting-edge medical solutions for military, law enforcement, and civilian responders worldwide. With a relentless commitment to quality and reliability, TacMed empowers individuals and organizations to respond effectively to life-threatening situations. Join us as we explore the forefront of medical innovation and discover how TacMed Solutions is revolutionizing tactical medical care.

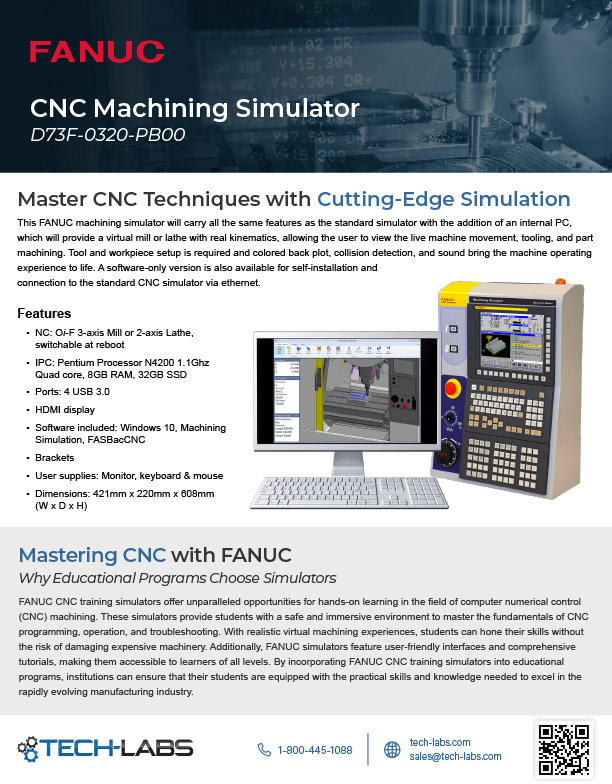

Master CNC Techniques with Cutting-Edge Simulation

Experience the ultimate in CNC machining simulation with FANUC's innovative simulator. This advanced system includes all the features of our standard simulator, enhanced by an internal PC. Delve into a virtual world of milling or lathe operations with authentic kinematics, granting users a firsthand view of machine movement, tooling, and part machining. From setup to execution, enjoy a lifelike experience with the colored back plot, collision detection, and sound effects. For seamless integration, opt for our software-only version, enabling self-installation and connection via ethernet to our standard CNC simulator.

Features

- NC: Oi-F 3-axis Mill or 2-axis Lathe, switchable at reboot

- IPC: Pentium Processor N4200 1.1Ghz Quad core, 8GB RAM, 32GB SSD

- Ports: 4 USB 3.0

- HDMI display

- Software included: Windows 10, Machining Simulation, FASBacCNC

- Brackets

- User supplies: Monitor, keyboard & mouse

Mastering CNC with FANUC

Why Educational Programs Choose FANUC Simulators

Discover why educational institutions worldwide use FANUC CNC training simulators for immersive learning experiences in computer numerical control (CNC) machining. FANUC simulators provide students with a safe environment to master CNC programming, operation, and troubleshooting, all without the risk of damaging expensive machinery. FANUC's simulators provide realistic virtual machining experiences and intuitive interfaces to learners of all levels. By integrating FANUC CNC training simulators into their programs, institutions ensure students are equipped with the practical skills needed to thrive in the manufacturing industry's ever-evolving landscape.

Discover the backbone of fluid transfer in industries globally with centrifugal pumps, efficiently propelling fluids with precision and power.

Experience hands-on learning like never before with Amatrol’s 950-PM1. Dive into the mechanics of centrifugal pumps and their diverse applications, from high-flow, low-pressure scenarios to managing an array of fluids, including water, chemicals, and food-grade substances.

Our robust and top-tier system empowers learners to master the installation, operation, and maintenance of centrifugal pumps. Delve into crucial topics such as pump sizing, mechanical seal installation, and effective troubleshooting, all while gaining invaluable experience with authentic industrial equipment.

Unveil the potential of this learning system as it expands to encompass a multitude of pump types and operations, from series and parallel setups to turbine, diaphragm, and magnetic pumps.

Ready to elevate your understanding of centrifugal pumps? Explore the Centrifugal Pump Learning System and its expansion options.