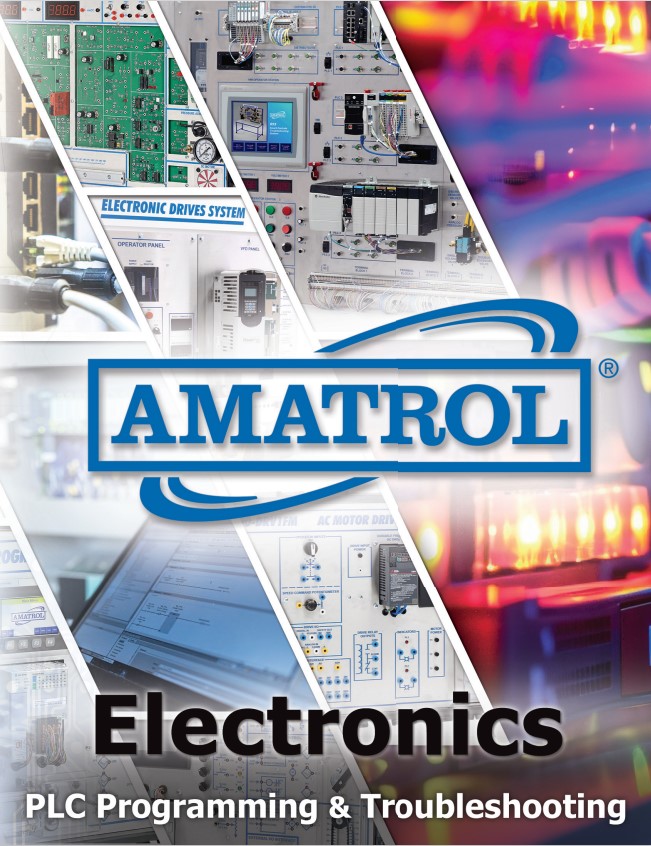

Electronics PLC Programming & Troubleshooting Training

Amatrol’s Electronics PLC Programming and Troubleshooting systems deliver industry-relevant, hands-on training with real-world components from leading manufacturers like Allen-Bradley, Siemens, and Mitsubishi. These systems teach critical automation skills including PLC operation, ladder logic programming, motor control, analog and digital I/O, event sequencing, and systematic troubleshooting—all essential for success in modern manufacturing and industrial environments.

From fully integrated workstations to portable learning systems, Amatrol offers flexible solutions that support in-depth learning in both classroom and on-site settings. Each system features interactive multimedia curriculum and FaultPro software for realistic fault insertion and diagnostics practice, ensuring learners build confidence in diagnosing and resolving real-world automation issues. Prepare students or trainees for tomorrow’s workforce with advanced PLC training that meets the needs of today’s technology.

At LIFT’s advanced manufacturing headquarters in Detroit, training the future workforce is a core mission. This video takes you inside the LIFT Learning Lab, where students engage with hands-on Amatrol training systems—from robotics and hydraulics to electronics and pneumatics. The lab features cutting-edge equipment, including the Pegasus robot, to help learners build real-world technical skills.

Hear from STEM Talent Program Manager Bernie Simms, Learning Lab Manager Jihad Mims, and Instructor Isaac Vanover as they highlight the impact of the IGNITE: Mastering Manufacturing program, developed in partnership with Amatrol. With students gaining confidence and exploring career paths in welding, automotive, and smart manufacturing, the program is truly igniting passion and purpose in the next generation of skilled workers.

This video highlights the impressive Industrial Tech-Ed program at Williams Bay High School in Wisconsin, where students gain real-world experience with advanced automation and Industry 4.0 technologies. The elective program offers hands-on training with pneumatic controls, AC/DC electrical systems, smart sensors, hydraulic systems, and industrial robotics.

Led by instructor Jacob White, the program empowers students to not only understand how each system functions but also how to integrate them creatively. By learning to think critically and problem-solve using interconnected technologies, students build a strong foundation for future careers in modern manufacturing environments.

Explore Ivy Tech Lafayette’s vision for the future of manufacturing in this engaging video featuring Academic Dean Bryce Eaton and student Gage Baer. Through a dynamic partnership with Amatrol, Ivy Tech Lafayette provides hands-on training in a state-of-the-art manufacturing lab that mirrors real industrial settings—including fluid power systems and advanced automation cells.

With a strong emphasis on renewable energy and smart technologies, the Energy Technology and Advanced Manufacturing programs are equipping students with the skills needed to thrive in Indiana’s growing industrial landscape. Discover how Ivy Tech is fostering innovation, sustainability, and workforce readiness in the heart of the Midwest.

Experience the future of manufacturing with Lakeshore Technical College! In this video, Dean of Applied Technology and Economic Development Rachel Kroeplien is joined by instructors Matt Roskopf and Brendo Olds for an inspiring look at how hands-on training and Industry 4.0 certifications are transforming their students' futures.

Through a powerful partnership with Amatrol and SACA (Smart Automation Certification Alliance), Lakeshore’s advanced manufacturing lab mirrors real-world industrial environments—complete with fluid power systems, robotics, and cutting-edge automation technology. Learn how Lakeshore Tech is preparing Wisconsin’s workforce for a rapidly evolving industry and helping students ignite a passion for innovation and technical careers.

Amatrol’s Portable Electric Motor Control Troubleshooting Learning System (990-MC1F) delivers essential skills training in the operation, installation, and troubleshooting of AC motor relay control systems. This compact, portable trainer includes industry-standard components such as a 3-phase AC squirrel cage motor, drum switch, reversing motor contactors, and safety devices like lockout/tagout—making it ideal for both classroom and on-site industrial training.

Learners use interactive eLearning curriculum and a virtual simulator to develop real-world skills like wiring pushbutton-activated circuits, configuring reversing motor starters, and safely operating control systems. The system also integrates FaultPro, Amatrol’s computer-based fault insertion software, allowing users to troubleshoot realistic scenarios such as 3-wire motor control systems. Complete with an instructor’s guide, installation guide, and student reference materials, the 990-MC1F supports flexible and scalable motor control training programs.

This video provides an inside look at the Portable Smart Process Sensor Learning System (990-SD20) from Amatrol—a compact, hands-on trainer designed to teach key Industry 4.0 skills. As industries embrace the Industrial Internet of Things (IIoT) and cloud-based automation, this system offers learners experience with the smart sensor technologies driving modern process control systems.

Learners engage with a range of smart sensors, including analog pressure sensors, electromagnetic flow sensors, ultrasonic level sensors, and point level sensors. The system also includes practical applications and real-world components such as an IO-Link Master, PC-based software, and simulations for level and flow sensing. With built-in curriculum, learners gain both technical know-how and a strong conceptual understanding of IIoT, edge and cloud computing, and data analytics in industrial environments.

Accelerate Welding Education with VRTEX® VR Systems

Build Confidence, Cut Costs: Discover Lincoln Electric's Virtual Welding Solutions

Explore a revolutionary way to train welders with the VRTEX® Virtual Reality Welding Training Platform from Lincoln Electric. Whether you're an educator, workforce trainer, or industry professional, the VRTEX® system offers a hands-on, immersive training solution that reduces costs and accelerates skill development.

- Reduce training time by up to 23%

- Increase certification rates by up to 42%

- Eliminate consumables like metal coupons, gas, and electricity

- Improve safety with no sparks, fumes, or heat

- Boost student confidence with real-time feedback and repetition

With optional oxy-fuel cutting, SMAW, GMAW, and GTAW modules, VRTEX® gives learners the ability to master multiple welding techniques in a virtual environment. Available in compact and dual-user formats to fit any lab setup or budget.

Ready to level up your welding program? Download the catalog to explore all VRTEX® system options, features, and curriculum resources.

Virtual Reality Welding in Action: A Case Study from Chicago

Virtual Welding Saves Time and Materials

Discover how the Chicago Regional Council of Carpenters Apprentice and Training Center revolutionized their welding program with Lincoln Electric’s VRTEX® 360 Virtual Reality Welding Training Simulator.

Instructors saw dramatic results:

- Enrollment surged from 650 to 1,800 apprentices

- Saved tens of thousands of pounds of material

- Reduced electricity costs and increased training throughput

- Built student confidence before they ever struck a real arc

From new apprentices to seasoned journeymen, the VRTEX® created a safe, effective, and immersive environment that mimicked real welding scenarios—without sparks, fumes, or wasted steel. With instant feedback, visual cues, and replay mode, students learned faster and instructors taught more efficiently.

Want to see how they did it? Download the full case study and learn how VRTEX® is transforming welding programs across the nation.

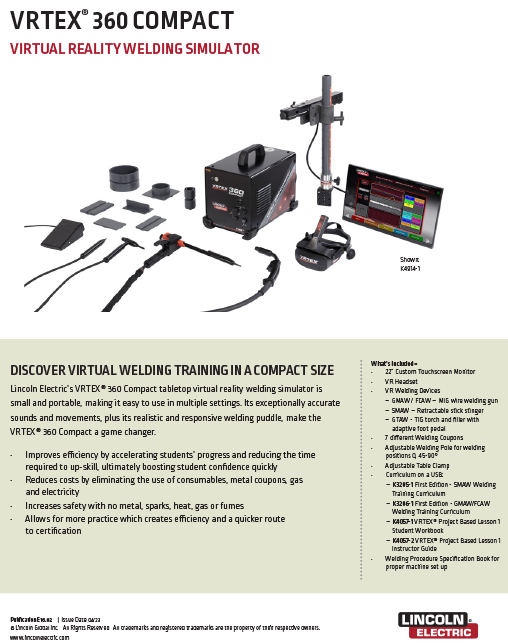

Your Tabletop Welding Lab—Anywhere

VRTEX® 360 Compact: Portable VR Welding Training

The VRTEX® 360 Compact brings professional-grade virtual welding to classrooms, labs, and mobile training sites. Designed by Lincoln Electric, this tabletop simulator offers the full range of weld types, positions, and materials—without the need for consumables, gas, or real flame.

- Simulates GMAW, SMAW, FCAW, and GTAW processes

- Includes realistic puddle, sparks, and sound feedback

- Virtual bend tests show cause of weld failure or success

- Replay mode and Weldometer™ track performance and savings

- Curriculum and instructor materials included via USB

Whether you're upskilling your workforce or starting a new CTE welding lab, the VRTEX® Compact makes it easy to scale quality instruction. Optional accessories include oxy-fuel cutting add-ons, travel cases, and table-mounted armrests.

Ready to reduce cost and improve results? Download the full product brochure and discover what the VRTEX® Compact can do for your welding program.

Pages

-

Item Number:602-PACProcess control systems maintain precise control of liquid and gas variables, such as liquid level, flow rate, pressure, temperature, and pH level. These multifaceted systems are a critical part of major industries like power generation, refineries, petrochemicals, chemical manufacturing, pharmaceuticals, biotechnology, and food processing and bottling.

-

Item Number:295-701DAC Worldwide's Temperature Regulator Cutaway (295-701) is a sectioned temperature regulator allowing for convenient classroom or lab training in the design, operation, construction, and maintenance of this common control device used in oil and gas production.

-

Item Number:273-920This 3-phase, squirrel-cage, induction motor cutaway supports industrial training activities related to electric motor types, as well as repair and troubleshooting. An integral horsepower, industrial-duty motor is modified for training purposes.

-

Item Number:273-925The 3-phase, squirrel-cage, explosion-proof induction motor cutaway supports industrial training activities related to electric motor types, as well as repair and troubleshooting. An integral horsepower, industrial-duty motor is modified for training purposes.

-

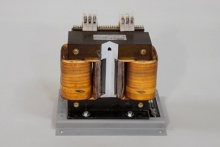

Item Number:273-915DAC Worldwide’s Three-Phase Transformer Cutaway (273-915) is a detailed and professionally-crafted three-phase transformer cutaway that depicts a common coaxially-wound, three-phase, delta-wye wired transformer.

-

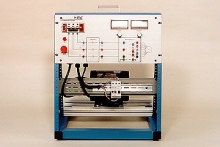

Item Number:412-000DAC Worldwide’s Three-Phase, Squirrel Cage Rotor, AC Motor Training System (412-000) provides a starting point for understanding a common, widely-used industrial induction motor. These self-starting, 56 frame, simply constructed motors are used in applications like generators or where low starting torque is required.

-

Item Number:TCRSimlog's simulation software puts you at the controls of a modern freestanding top-slewing tower crane with trolley jib. Instrument readings include working slew angle, working radius, lowering depth (hook height), and load weight. There is also a simulated three-way switch for hoist gear selection. You can even change the viewpoint during the simulation at the touch of a button.

-

DAC Worldwide’s training systems are designed to provide a realistic, hands-on learning experience in a variety of industrial sectors. Each system has the look and feel of real equipment learners might encounter on the job. Built with full-size, industrial-quality components, as well as high-durability, powder-coated surfaces throughout, DAC Worldwide's training systems allow for repeated use and rough handling.

-

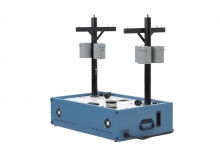

Item Number:491-000DAC Worlwide’s Transformer Connections Training System (491-000) replicates the conditions and circumstances that a utility worker encounters when making common transformer connections in the field.

-

Item Number:408-000

DAC Worldwide’s Transformer Wiring Training System (408-000) is a realistic training device that replicates the conditions and circumstances that an electrical worker encounters when making common power transformer connections in the field and industry. This self-contained, tabletop training system provides a safe, inexpensive, yet realistic alternative to paper-based learning without the danger of full-voltage field experience.