Empowering Education with Lincoln Electric

Hands-On CNC Plasma Cutting Experience for Students in 30 Minutes or Less

Lincoln Electric® CNC plasma cutting tables are the ideal addition to educational programs, providing students with real-world skills in precision metal cutting. Designed as fully integrated systems, these machines offer seamless operation, allowing instructors and students to focus on learning rather than troubleshooting equipment.

Why Choose Lincoln Electric® for Your Classroom or Training Lab?

- Turnkey Solutions for Educators: Fully assembled and ready to use—start teaching metal cutting skills the same day the table arrives.

- Integrated Design: Every component is engineered to work together, ensuring reliable performance and easy operation for students.

- Durable and Low Maintenance: Torchmate tables are built to handle the rigors of daily classroom use with minimal upkeep, so your focus remains on teaching.

- Industry-Standard Training: Equip students with hands-on experience using technology trusted by professionals in manufacturing and fabrication.

Whether you’re running a high school CTE program, a technical college course, or a workforce development initiative, Lincoln Electric® CNC plasma tables empower students with practical, job-ready skills in CNC programming and metal fabrication.

Empowering Workforce Development with Lincoln Electric® Torchmate

Waukesha County Technical College (WCTC) is a leader in workforce development, offering over 150 programs, including associate degrees, technical diplomas, apprenticeships, and short-term certificates. With Waukesha and Pewaukee, Wisconsin campuses, WCTC delivers hands-on training designed for immediate application in the workplace. As a proud partner of Lincoln Electric®, WCTC equips its students with cutting-edge tools and skills to meet industry demands.

Upgrading to the Torchmate 5100 for Better Learning Outcomes

In the Fall semester of 2022, WCTC upgraded its CNC plasma-cutting capabilities by investing in a Torchmate 5100 equipped with a FineLine® 170HD. This advanced system replaced their previous 2’x4’ Torchmate Growth Series tables. It enabled students to work on larger sheets and produce higher-quality cuts, even on thicker materials like half-inch aluminum and steel.

- Enhanced Precision: Achieves superior cut quality on a wide range of materials.

- Increased Capacity: Handles extended work hours, with students using the table for 20+ hours each week.

- Diverse Applications: Students create parts for welding classes, fire pits, metal décor, smoker grills, and more.

Real-World Training Leads to Career Success

WCTC’s Automated Cutting Processes program, part of the Automated Systems Technology curriculum, integrates CNC plasma cutting with robotics and programmable logic controllers (PLCs). Students gain hands-on experience operating advanced systems like the Torchmate 5100, learning automation principles critical in modern industries.

Success Stories

Graduates of the Automated Systems program have secured roles at industry leaders like Messer, a global provider of industrial and medical gases:

- Three alumni now serve as application engineers.

- One graduate works as a product manager.

- Another alum is a software engineer.

These career placements highlight how WCTC’s partnership with Lincoln Electric® empowers students to achieve high-level roles in their fields.

Lincoln Electric®: Partnering with Educators

Lincoln Electric® is committed to supporting education by providing instructors with state-of-the-art equipment and comprehensive training. WCTC’s arsenal of Lincoln Electric products includes:

- Torchmate 5100 with FineLine® 170HD

- Tomahawk® manual plasma cutters

- Robot welding machines

- Power Wave®, Flextec®, and Precision TIG® welders

After the Torchmate 5100 purchase, Lincoln Electric sent expert trainers to WCTC, ensuring educators were equipped to maximize the machine’s capabilities.

“Lincoln Electric is a trusted name with a long history. They have individually focused teams that perfect each product. They’ve done great for WCTC, and I would absolutely recommend the Torchmate 5100.” – Brad LeTourneau, WCTC Metal Fabrication and Welding Instructor

Investing in the Future Workforce

By partnering with schools like WCTC, Lincoln Electric® ensures the next generation of welders, engineers, and fabricators is well-prepared for industry challenges. With innovative solutions like the Torchmate 5100, students gain the skills and confidence to succeed in their careers.

Ready to bring Lincoln Electric® solutions to your school? Contact us today to learn more about how our training systems can empower your students.

Empowering Education with Torchmate® CNC Plasma Cutting Tables

Torchmate® offers state-of-the-art CNC plasma cutting solutions designed specifically for educational institutions. The Torchmate EDU catalog highlights tools, training programs, and resources to equip educators with everything they need to prepare the next generation of skilled manufacturing, welding, and robotics workers.

Key Features of Torchmate® CNC Plasma Cutting Tables

- Plug-and-Play Systems: Torchmate 4000 Series tables are ready to run in just 30 minutes, ensuring minimal downtime and seamless classroom integration.

- Comprehensive Educational Packages: Includes unlimited student licenses, the ProText module (1,300+ fonts, 4,000+ clip art images), and robust CAD/CAM software tailored for classroom use.

- Advanced Technology: Proprietary motion control systems, industrial-grade user interfaces, and optional castor wheels for mobility.

- Enhanced Training Opportunities: Torchmate University and Academy provide video tutorials, live training sessions, and hands-on learning experiences for both students and instructors.

Models Featured in the Catalog

- Torchmate 4410 (4x4 ft):

Compact and powerful, ideal for smaller classrooms with limited space. Perfect for medium-sized projects and foundational training. - Torchmate 4810 (4x8 ft):

Designed for larger material handling and increased productivity. Suitable for schools with advanced manufacturing programs. - Torchmate 4510 (5x10 ft):

Built for large-scale, professional-grade projects. Equipped for cutting thick materials and accommodating full sheets of metal. - Torchmate 4000 TC Pipe & Tube Cutter:

Specialized for educational environments, allowing students to cut and profile pipes with precision while learning real-world automation skills.

Complete CNC Curriculum

The Torchmate CNC Plasma Cutting Curriculum provides a structured and comprehensive approach to teaching CAD, CAM, and CNC operations. Key highlights include:- 11 Chapters of Instruction: Covers topics like coordinate systems, G-code programming, and Torchmate CAD.

- Hands-On Projects: Guides students through the design and fabrication process, ensuring practical skill development.

- Instructor-Friendly Design: Lesson plans, quizzes, and assignments tailored for easy implementation.

Training & Support for Educators

Torchmate provides extensive training and support to ensure successful classroom integration:

- Torchmate Academy: High-definition video walkthroughs covering machine operation and maintenance.

- On-Site Training: Customized sessions with factory-trained technicians at your location.

- Virtual & Classroom Training: Options include Torchmate University, live virtual classes, and in-person seminars.

Why Choose Torchmate for Education?

- Industry-Standard Tools: Equip students with the same technology used by professionals in manufacturing and robotics.

- Seamless Integration: Ready-to-run systems with full educational support.

- Future-Ready Curriculum: Prepare students for careers in CNC operations, metal fabrication, and advanced manufacturing.

Download the Catalog

Discover how Torchmate CNC plasma cutting tables can transform your educational program. Download the full Torchmate EDU Catalog to explore tools, curriculum, and training resources designed to empower educators and students alike.

Unlock Advanced CNC Plasma Cutting with Torchmate® 4000 Series

Torchmate®, a Lincoln Electric® company, introduces the 4000 Series CNC plasma cutting systems—designed for high performance and efficiency. Whether for education, small fabrication shops, or industrial applications, the 4000 Series offers cutting-edge technology, durability, and unmatched support to meet diverse cutting needs.

Key Features of the 4000 Series

- Ready to Run in 30 Minutes: Fully assembled and pre-configured systems allow you to start cutting immediately.

- Advanced Performance: Faster cycle times (2.5x improvement), 65% faster cut speeds, and reduced operational costs.

- Enhanced User Interface: Integrated touchscreen HMI, 27-part shape library, and optional clip art gallery with over 6,000 files.

- Durable and Dependable: Engineered for exceptional repeatability, with best-in-class warranties (2 years on tables, 3 years on power supplies).

Torchmate 4000 Series Models

Torchmate 4400 (4x4 ft)

Compact and powerful, ideal for smaller fabrication shops or classrooms with limited space.

- Dimensions: 74” x 67” x 63”

- Water Capacity: 60 gallons

- Material Capability: Cuts up to 1" mild steel

Torchmate 4505 (5x5 ft)

A versatile option for mid-size projects and general fabrication.

- Dimensions: 86” x 79” x 63”

- Water Capacity: 85 gallons

Torchmate 4800 (4x8 ft)

Designed for larger cutting areas, reducing material waste and increasing productivity.

- Dimensions: 74” x 114” x 63”

- Water Capacity: 107 gallons

Torchmate 4510 (5x10 ft)

Built for large-scale applications, offering superior cutting capabilities for industrial needs.

- Dimensions: 86” x 138” x 63”

- Water Capacity: 140 gallons

Education Packages

Torchmate 4000 Series offers tailored solutions for schools and training programs:

- Ready-to-Run Systems: Fully assembled and optimized for classroom integration.

- Unlimited CAD Licenses: Equip every student with hands-on design and programming experience.

- Comprehensive Support: Includes advanced online training, private educator communities, and interactive learning resources.

Why Choose Torchmate 4000 Series?

- Seamless Integration: Rapid delivery and setup minimize downtime.

- Cost-Effective Operation: Save up to 45% on consumable costs with FlexCut® technology.

- Industry-Leading Warranty: All components backed by Lincoln Electric’s trusted service.

Download the Catalog

Explore the full Torchmate 4000 Series Catalog to discover detailed specifications, features, and training resources. Jumpstart your training with advanced CNC plasma cutting today.

Complete CNC Package for Schools

Check out the Torchmate CNC plasma table education packages! These packages are the ideal choice for the education setting with unlimited student licenses, superb training options, and numerous other online learning tools to keep your students engaged.

Discover Why Instructors Nationwide Choose Amatrol

Every summer, Career and Technical Education (CTE) instructors nationwide gather at Amatrol’s headquarters to participate in our hands-on training sessions. These sessions empower educators with the tools and knowledge they need to deliver cutting-edge technical education in their classrooms.

Hear from Instructors Themselves

What makes Amatrol trainers and eLearning stand out? Don’t just take our word for it—hear directly from the instructors who use them daily. Watch the video below to discover how Amatrol solutions help educators:

- Engage students with hands-on learning experiences

- Build workforce-ready skills

- Deliver industry-standard technical training

Amatrol trainers and eLearning solutions are trusted by educators worldwide for their:

- Comprehensive Curriculum: Covering a wide range of technical skills, from automation to HVAC systems.

- Real-World Applications: Preparing students for today’s workforce with practical, hands-on training.

- Ease of Use: Intuitive designs and user-friendly resources make integration into classrooms seamless.

Instructor Training Sessions to see how Amatrol can transform your classroom.

Fronius is a global leader in welding technology, renowned for its innovative solutions catering to various industries. With a focus on precision, efficiency, and quality, Fronius offers advanced welding systems that enhance productivity and ensure superior results for both manual and automated welding applications. Their products are designed to meet the rigorous demands of automotive, aerospace, and manufacturing industries, making Fronius a trusted partner for businesses looking to optimize their welding processes.

Fronius continuously pushes the boundaries of technology by integrating smart features, including digital connectivity and process monitoring, ensuring that its welding systems remain at the forefront of Industry 4.0 advancements. With a strong commitment to sustainability, Fronius also provides energy-efficient solutions that reduce operational costs and minimize environmental impact, aligning with the needs of modern industry professionals.

Welding Training for the Future

Hands-on training meets automation! The APT Mod-Weld is a cutting-edge robotic welding system designed for education and industry, integrating FANUC’s CRX-10 collaborative robot with Fronius TPSi 400 welding technology.

Why choose the Mod-Weld?

- Trains welders and programmers—bridging the gap between manual welding and automation

- Industry-approved technology—used in colleges, high schools, and industrial training centers

- Safety first—FANUC’s CRX stops instantly on impact, ensuring a secure training environment

- User-friendly interface—simplifies robotic programming for students and professionals

Want to see the APT Mod-Weld in action? Schedule a demo today!

Innovations in Technical Training & Workforce Development

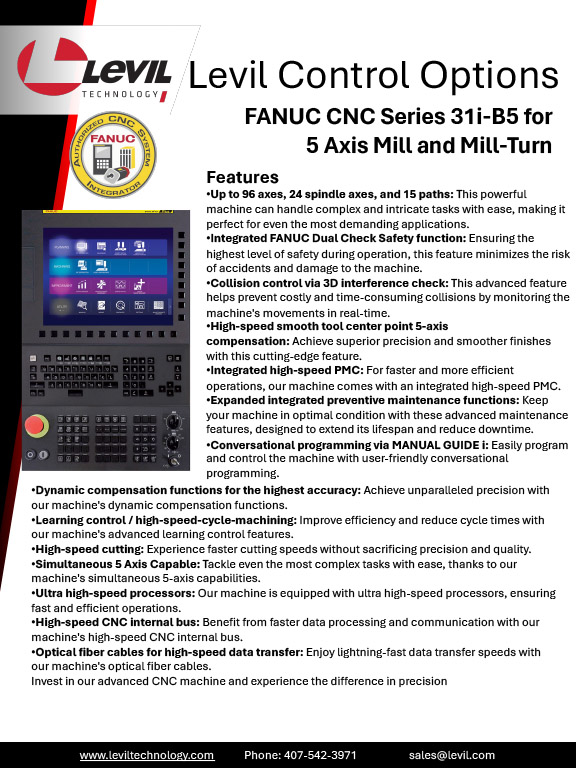

Levil Control Options for 5-Axis Mill and Mill-Turn

Experience unmatched performance, precision, and control with the FANUC CNC Series 31i-B5. This flyer provides a detailed overview of FANUC’s high-performance CNC system, designed to support even the most demanding machining operations.

Key Features Include:

- Up to 96 axes, 24 spindle axes, and 15 paths: Handle highly complex machining operations with ease.

- Integrated FANUC Dual Check Safety: Maximize operator safety and machine protection during every cycle.

- 3D Interference Check: Prevent collisions and downtime through real-time monitoring and collision control.

- High-Speed Smooth Tool Center Point Compensation: Ensure superior accuracy and finish on intricate parts.

- Integrated High-Speed PMC: Increase efficiency and cycle performance with faster processing.

- Preventive Maintenance Functions: Extend machine life with smart, built-in maintenance tracking.

- MANUAL GUIDE i: Simplify CNC programming with intuitive, conversational controls.

- Dynamic Compensation Functions: Maintain peak accuracy and control with real-time adjustments.

- Learning Control / High-Speed Cycle Machining: Minimize machining times while maintaining quality.

- Simultaneous 5-Axis Machining: Execute advanced geometries and tight tolerances with ease.

- Ultra High-Speed Processors & CNC Internal Bus: Optimize data handling and reduce latency.

- Optical Fiber Communication: Accelerate data transfer for smoother CNC system performance.

Download the brochure now to explore how the FANUC CNC Series 31i-B5 can enhance your shop floor or training environment.

Need help integrating FANUC controls into your curriculum or facility? Contact our team to learn more about automation and CNC training solutions.