Basic Electrical Machines Learning System

Amatrol’s Basic Electrical Machines Learning System (85-MT2) teaches electric machines commonly found in industrial, commercial, and residential applications: single-phase AC motors, three-phase AC electric motors, and DC electric motors. Learners practice industry-relevant skills including operation, installation, analyzing performance, and selecting electric machines for various applications.

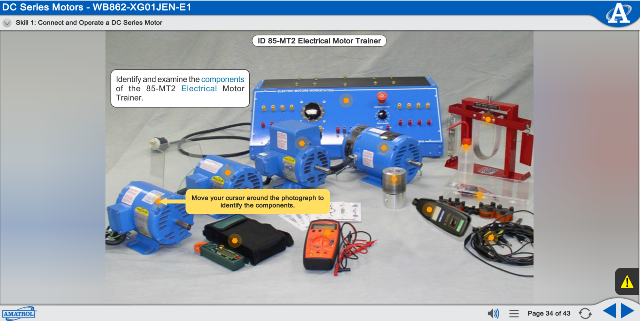

Amatrol’s 85-MT2 features a number of industrial machines, including an AC multi-purpose, single-phase motor, a split-phase motor, a DC motor/generator, and a 3-phase induction motor. This learning system also includes an integrated base test unit, phototachometer, lead set, prony brake, handheld clamp-on multimeter, handheld digital multimeter, world-class curriculum, and a student reference guide. This system uses industrial quality components both to help learners become better prepared for what they will encounter on the job and to withstand frequent use.

Teach Skills Hands-On

Industrial Standard Machines and Wiring Terminology

The 85-MT2’s electrical machines are off-the-shelf industrial units that provide learners with real-world experience in installation and alignment of industrial motors. Each unit is rated at 1/3 Hp, which is the minimum size at which motor performance data models the performance of larger motors. Units are connected to load devices through an industrial standard flexible coupling that allows for learning of shaft alignment techniques.

Each machine’s power connections use industrial standard wiring terminology (e.g. T numbers) so that learners study how to connect electric machines in the same manner as they would on the job. The 85-MT2 uses replaceable wiring diagram panels for learning evaluation.

Industrial Loads with Safety

The integrated test unit has provisions for mounting a prony brake to load motors so learners can observe their operation under real world conditions. The unit also mounts two coupled machines to demonstrate generator operation. Safety devices include a 3-phase circuit breaker and a keyed emergency stop pushbutton. The pocket digital multimeter allows learners to analyze the performance of each machine in a realistic setting just as they would in the field. Built-in variable AC and DC power supplies enable learners to study the operation of AC and DC machines under a variety of conditions. Its unique switching system has an 11-position switch that allows learners to read current and voltage in all three legs of power without disconnecting leads.

Interactive eLearning Curriculum

Interactive Electrical Motors eLearning Curriculum

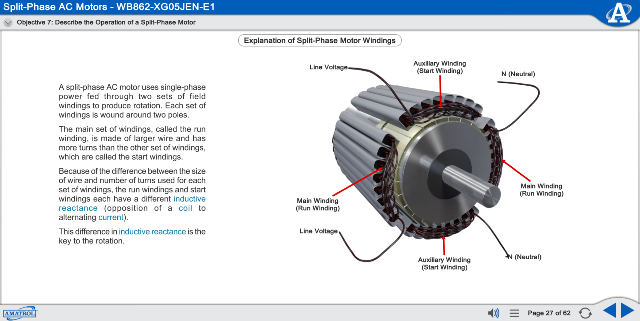

Amatrol's basic electrical machines training system features interactive eLearning curriculum that integrates various types of learning methods to create an engaging, effective learning experience. Amatrol’s multimedia eLearning curriculum includes text with voiceovers, videos, 3D animations, pictures, and interactive activities, quizzes, and self-reviews. Specific electric motors topics covered include: DC series, shunt, and compound motors; motor speed, torque, and performance; split-phase and capacitor-start AC motors; permanent-capacitor and two-capacitor motors; and three-phase AC induction motors. Within these topics, learners will study objectives like connecting and operating a cumulative DC compound motor; selecting the correct DC motor for an application based on motor performance characteristics; reversing the rotation of a capacitor-start motor; and determining how to connect a three-phase motor to operate on the available voltage.

Free Learning Management System (LMS)

Amatrol eLearning is easy-to-use for both students and instructors. Its web-based interface is simple to navigate and available on any WebGL-compatible Internet browser. Instructors love Amatrol eLearning for its simple, yet sophisticated Learning Management System (LMS). The LMS allows instructors to create custom courses, monitor student participation, track course progress, assess knowledge levels prior to a course, and test knowledge levels after completion. Learners appreciate the fact that they can start and stop as needed, moving throgh each Amatrol course at their own pace. If a self-review reveals that they didn’t understand a particular topic as well as they thought they did, they can revisit it before moving on.

Hand-Held Digital Multimeter

The hand-held digital multimeter allows learners to analyze the performance of each machine in a realistic setting just as they would in the field. Built-in variable AC and DC power supplies enable learners to study the operation of AC and DC machines under a variety of conditions. Its unique switching system has an 11-position switch that allows learners to read current and voltage in all three legs of power without disconnecting leads.

Student Reference Guide

A sample copy of this course’s Student Reference Guide is included with the learning system. Sourced from the multimedia curriculum, the Student Reference Guide takes the entire series’ technical content contained in the learning objectives and combines them into one perfect-bound book.

Key Features

- Industrial Standard 1/3 Hp Motors

- Heavy Duty Welded Steel Workstation

- Industrial Loads with Prony Brake

- Industrial Standard Wiring Terminology

- Industrial Safety Devices

- Multimedia Curriculum Available

- Student Reference Guide

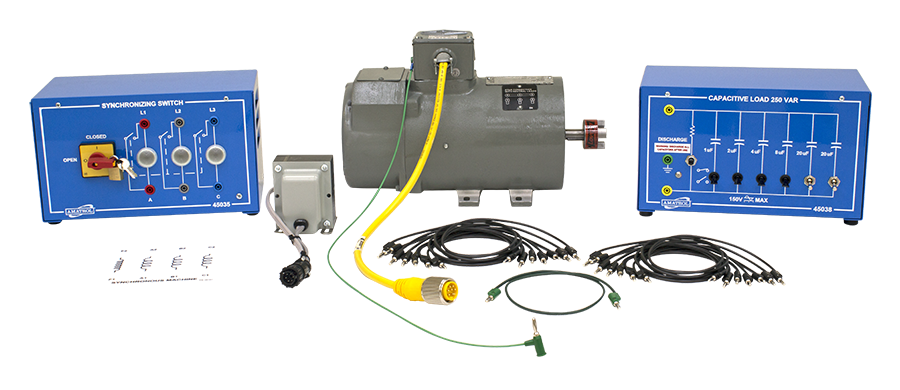

Product Options

Electrical Machines Multimedia (CD-B862)

Basic electrical machines introduces electrical circuits and works through many industry tasks in Electrical Systems including DC Series Motors, DC Shunt and Compound Motors, Motor Speed and Torque, Motor Performance, Split-Phase AC Motors, Capacitor-Start AC Motors, Permanent-Capacitor, and Two-Capacitor Motors, and Three-Phase AC Induction Motors.

Engaging Multimedia

Amatrol’s extensive, thorough multimedia covers electrical basics such as electrical machines. Interactive screens paired with instructive graphics teach electrical machines topics from rotating electrical motors to three-phase AC induction motors. With the optional hardware, learners can then apply this theoretical knowledge to immediate hands-on skills. For example, learners study how to change the direction of rotation of a DC motor and then on their own manually reverse the rotation of a DC series motor. This combination of theory and practice ingrains concepts in a learner’s mind and makes more advanced topics easier to comprehend. (References 85-MT2)