Electric Motor Control Learning System

Amatrol’s Electric Motor Control Learning System (85-MT5) covers electric relay control of AC electric motors found in industrial, commercial, and residential applications. Learners study industry-relevant skills including how to operate, install, design, and troubleshoot AC electric motor control circuits for various applications.

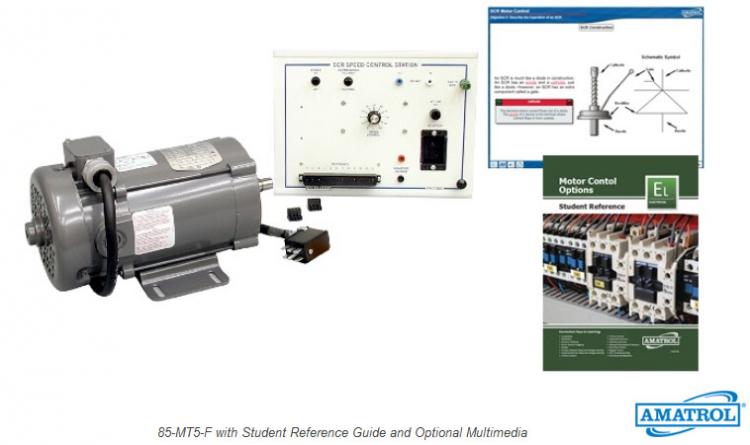

The 85-MT5 includes a bench top-mount control workstation, motor workstation, AC induction motor, control component panels, multimeter, lead set, and student curriculum that is unmatched within the industry. This system uses industrial quality components to help learners become better prepared for what they will encounter on the job. Some of the major components that learners will work with include a control transformer, reversing contactors, manual motor starter, multi-function timer, and control relays.

The 85-MT5 teaches learners how to troubleshoot motor control circuits under realistic conditions. Circuit faults can be introduced using either the manual fault insertion, supplied as a standard, or through the optional Computer-Based Fault Insertion System (890-FTS-1) which includes Amatrol’s FaultPro, the industry’s only electronic-fault insertion software.

Industry-Standard Motor Control Components

The 85-MT5’s electric motor and control components are off -the-shelf industrial standard components that provide learners with real world experience in installation and control of industrial motors. The motor is rated at 1/3 Hp and uses industrial standard T-number wiring terminology. Units are connected to load devices through an industrial standard flexible coupling that provides for learning of shaft alignment techniques. Safety is emphasized throughout the curriculum and in the hardware design. Safety devices include a lockout/tagout system and grounded connections for individual components in the system. Learners use these safety devices each time they set up a circuit.

Heavy Duty Workstation with Storage

The 85-MT5 Motor Control System Workstation’s welded-steel construction provides a sturdy work surface for mounting control components. Each component is mounted directly onto an individual heavy-duty steel panel, which easily slides into the workstation and locks into place, allowing learners to quickly set up a variety of circuit applications.

Extensive Curriculum Builds Industry Skills

The 85-MT5’s curriculum is unmatched within the industry for its breadth and depth of motor control topics and hands-on skills. This curriculum advances through topics like three-wire start/stop control, reversing magnetic motor starter, and on-delay and off-delay timers that can then be used to practice hands-on skills. As an example, learners will study about the function, operation, and types of control relays and then practice hands-on skills by actually connecting and operating a control relay in a circuit.

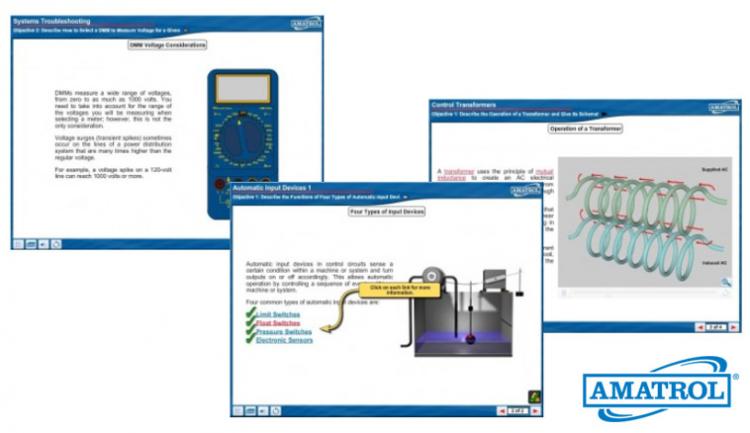

The 85-MT5’s also offers optional multimedia curriculum that combines text, audio, 3D illustrations, and loads of interaction to fully engage learners as they begin at the foundation of motor control knowledge.

Superb Troubleshooting Skills

The 85-MT5 features a variety of manual faults that allows learners to practice real world troubleshooting on actual industrial components. Troubleshooting skills include testing an indicator lamp, manual switch, control relay, motor contactor, overload relay, and many more!

Optionally, the 85-MT5 offers electronically inserted faults using the 890-FTS-1 Computer-Based Fault Insertion System. The 890-FTS-1 uses Amatrol’s electronic fault insertion software, FaultPro, which allows learners to practice troubleshooting over 35 faults on this learning system.

Key Features

- Industrial Standard 1/3 Hp Motor

- Heavy Duty Welded Steel Workstation

- Industrial Standard Wiring Terminology

- Industrial Safety Devices

- Built-in Manual Fault Insertion

- Optional Computer-Controlled Fault Insertion

- Multimedia Curriculum Available

- Student Reference Guide

Additional Requirements

- Prony Brake (EL613-43)

- Hand Tool Package (41202)

- Compressed Air (50 psi)

- Electricity (208 VAC/60 Hz/3 phase)

Product Options

- Electric Motor Control Multimedia

- 6' Workstation (82-610)

- Motor Braking Training System (85-MT5-A)

- Reduced Voltage Starting Training System (85-MT5-B)

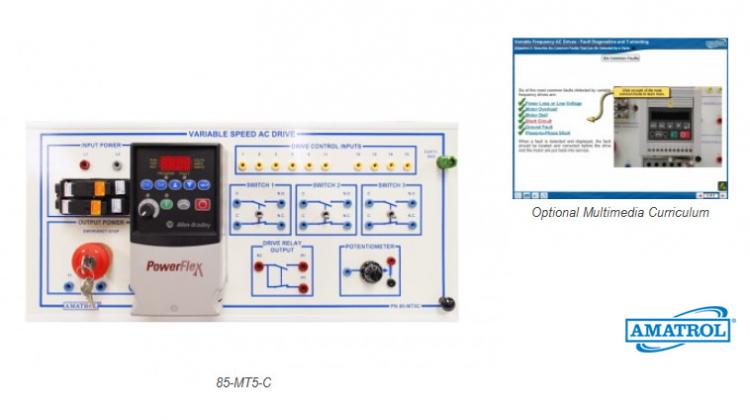

- Variable Frequency AC Drive Training System (85-MT5-C)

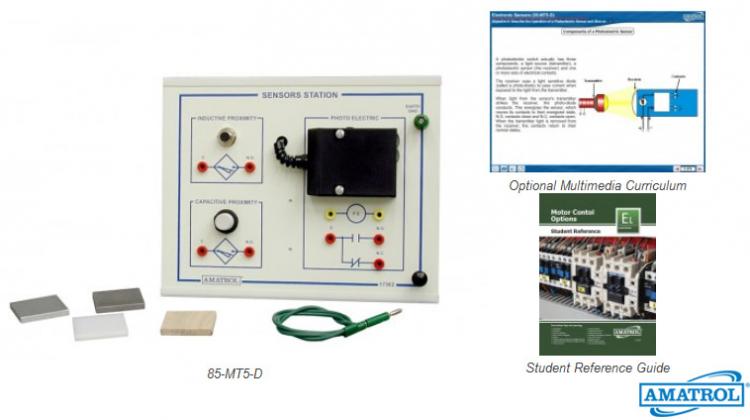

- Electronic Sensors Training System (85-MT5-D)

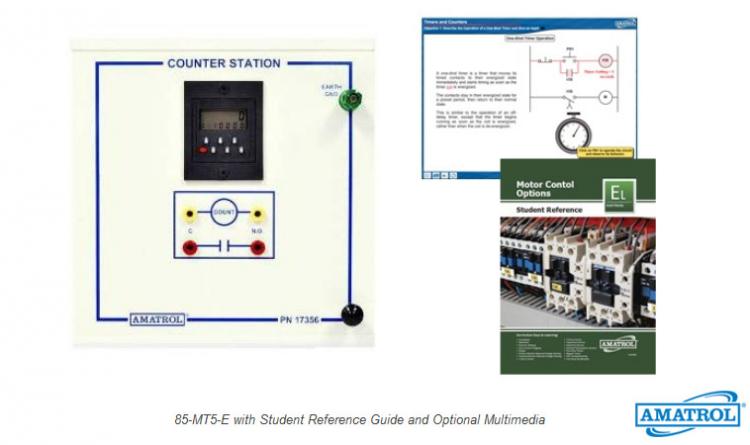

- Electronic Counter Training System (85-MT5-E)

- DC Drive with SCR Speed Control Training System (85-MT5-F)

- Fault Troubleshooting Training System (890-FTS1)

Electric Motor Control Multimedia (M17401)

Electric motor control teaches electric relay control of AC electric motors found in industrial, commercial, and residential applications. Learners gain understanding of the operation, installation, design, and troubleshooting of AC electric motor control circuits for many common applications. Develops skills in interpreting schematics, system design, motor start / stop circuits, motor sequence control, reversing motor control, and motor jogging. Safety is emphasized throughout, highlighting motor safety, lockout/ tagout and safety interlocks.

Interactive Multimedia

Amatrol’s extensive, thorough multimedia covers electrical basics such as electric motor control. Interactive screens paired with instructive graphics teach an array of electric motor control topics from control transformers to reversing motor control. With the optional hardware, learners can then apply this theoretical knowledge to immediate hands-on skills. For example, learners study the operation and application of a two-wire motor control circuit and then connect and operate this circuit for themselves. This combination of theory and practice ingrains concepts in a learner’s mind and makes more advanced topics easier to comprehend. (References 85-MT5)