Amatrol’s Intermediate Hydraulics training system (85-IH) introduces advanced hydraulic components (pilot-operated check valves, two-position directional control valves, telescoping cylinders, etc.), explains how each works, and then shows how they relate to real-world applications in elevators, punch presses, backhoes, and many more. This approach to curriculum is an Amatrol signature: reinforce both theory and practice to produce a well-rounded understanding of the topic. Learners will be able to understand concepts like pressure intensification and cylinder regeneration while also being able to operate, install, design, and troubleshoot hydraulic components.

Intermediate Hydraulics includes directional control valves, relief valves, a flow control valve, a check valve, and an accumulator. Amatrol training systems use industrial-grade components displayed on hand-welded, painted and silk-screened panels, and workbenches made from top-flight materials. This precise attention to quality and detail ensures a tough, visually appealing, user-friendly design that will last for years and help learners gain experience with components they’ll actually see on the job.

The skills and principles offered in Intermediate Hydraulics build on the fundamentals taught by the Basic Hydraulics (85-BH), but also lead to additional, more advanced learning systems such as Advanced Hydraulics (85-AH) and Electro-Hydraulics (85-EH). The advanced hydraulics training system teaches learners about hydraulic performance analysis and maintenance, while the electro-hydraulics training system (which is used in several exercises with the intermediate hydraulics training system) introduces electrical relay control of hydraulic systems.

Amatrol’s Intermediate Pneumatics Training System (85-IP) builds on basic pneumatic skills by introducing more advanced concepts such as air logic, ways to decelerate a pneumatic cylinder, and how to prevent condensation in a pneumatic circuit. Learners will have the opportunity to study these concepts while working with a hands-on training module, which enables practicing skills such as connecting and operating a two-way valve and changing an air filter element; this approach of simultaneously teaching theory and practice reinforces each element and results in a thorough understanding of the topic.

The Intermediate Pneumatics training system includes directional control valves, check valve, pneumatic cylinder, Venturi block, assorted filter elements, and much more. Amatrol’s commitment to using top-flight, industry-standard materials ensures that learners work with components they’ll actually see on the job. This attention to quality and detail culminates in a durable, attractive, user-friendly industrial training system that will last for years.

After completing the Intermediate Pneumatics curriculum, learners can continue to build on these skills by moving on to Amatrol’s Advances Pneumatics (85-AP) and the Pneumatics Troubleshooting (950-PT1) training systems. Advanced Pneumatics covers topics such as motor loads, pneumatic cylinder loads, and quick exhaust valves, while Pneumatic Troubleshooting is the first product to offer a realistic troubleshooting experience for learners because the faults are inserted throughout the system.

Amatrol’s Basic Electrical Machines Learning System (85-MT2) teaches electric machines commonly found in industrial, commercial, and residential applications: single phase AC motors, three-phase AC electric motors, and DC electric motors. Learners practice industry-relevant skills including operation, installation, analyzing performance, industrial motor wiring, and selecting electric machines for various applications.

The 85-MT2 features a number of industrial machines, including an AC multi-purpose single phase motor, a split phase motor, a DC motor/generator, and a 3-phase induction motor. This learning system also includes an integrated base test unit, lead set, prony brake, handheld clamp-on multimeter, handheld digital multimeter, world-class curriculum, and a student reference guide. This system uses industrial quality wiring schematic components both to help learners become better prepared for what they will encounter on the job and to withstand frequent use.

Amatrol’s DC Generators Learning System (85-MT2B) teaches industry-relevant DC generator skills, including how to operate, install, analyze performance, and select generators for various applications. A generator is a device that creates DC electricity and can be found in diesel locomotives, as well as aircraft and marine systems. The DC generators training system requires the Basic Electrical Machines Learning System (85-MT2), as well as 208 VAC/60 Hz/3 phase power.

This industrial motor training system includes resistive load and inductive load units that connect to the DC generator supplied with the 85-MT2 to provide operation under various types of loads. Learners will use these components to study topics such as DC series generators, DC shunt generators, and DC compound generators. Amatrol learning systems feature a perfect combination of theoretical knowledge and hands-on skill building to reinforce each in a learner’s mind and strengthen comprehension for more advanced skills.

Amatrol’s Alternator/Synchronous Motor Learning System (85-MT2C) adds to the Basic Electrical Machines Learning System (85-MT2) to teach skills related to alternators and synchronous motors commonly found in industrial applications. Alternators provide a mobile source of AC electrical power while synchronous motors reduce power costs by correcting the overall power factor in a plant. Learners will study industry-relevant skills in industrial motor training, including how to operate, install, and analyze the performance of alternators and synchronous motors.

The alternator and synchronous motor training system includes capacitive load, combination synchronous motor/alternator, and synchronizing lights/switch units. The capacitive load unit combines with the 85-MT2 to provide operation under various types of loads. In addition to industrial components, this training system includes in-depth curriculum, an instructor’s guide, and a student reference guide. The highly-interactive, multimedia curriculum covers major topical areas such as alternator output voltage and frequency, three dark synchronization method, and reversing a synchronous motor.

Amatrol’s Wound Rotor Motor Learning System (85-MT2D) covers the function, operation, and performance characteristics of wound rotor motors. While variable frequency drives (VFDs) and standard induction motors have replaced wound rotor motors in many applications, these motors are still used for heavy-duty, high torque applications such as industrial cranes and hoists. Amatrol’s wound rotor motor training system requires the Basic Electrical Machines Learning System (85-MT2) for use.

Wound rotor motor training includes a wound rotor speed controller, a wound rotor motor, banana leads, in-depth multimedia curriculum, an installation guide, and a student reference guide. These components will be used to study topics such as wound rotor speed control, performance characteristics, and motor reversing. Amatrol systems feature real-world, industrial-grade components for both durability and to facilitate learners in gaining hands-on practice with actual equipment that they’ll find in the field.

Amatrol’s Electric Motor Troubleshooting Learning System (85-MT2E), used in conjunction with the required Basic Electrical Machines Learning System (85-MT2), covers AC and DC motors troubleshooting and testing using a multimeter and a megger meter. The skills and knowledge covered by this system will prove invaluable for industrial maintenance technicians or anyone working in a field that uses AC and/or DC motors. This system covers major topics like AC and DC motor failures, common methods of diagnosing these failures by using a multimeter and megger meter, and troubleshooting these failures.

The 85-MT2E includes a motor connection box to practice hands-on skills, such as troubleshooting faults in a DC motor and AC single-phase and three-phase motors, evaluating DC electric motor commutator and brush health, and using a multimeter to test an AC motor start/run capacitor. Amatrol’s industrial training systems feature real-world, industry-grade components for durability that will stand up to frequent use and to allow learners to gain real-world competencies.

The AC Elector Motor Control Systems Trainer will give your students hands-on learning with motors found in industrial, commercial, and residential applications. It's versatile, comprehensive, and has eLearning built around it. Watch for a quick overview of the system.

Amatrol’s Electric Motor Control Learning System (85-MT5) teaches electric relay control of AC electric motors found in industrial, commercial, and residential applications. Learners study industry-relevant skills including how to operate, install, design, and troubleshoot AC electric motor control circuits for various applications.

The 85-MT5 includes a bench top-mount control workstation, motor workstation, AC induction motor, control component panels, multimeter, lead set, and student curriculum that is unmatched within the industry. This system uses industrial-quality components to train learners to become better prepared for what they will encounter on the job. Some of the major components that learners will work with include a control transformer, reversing contactors, manual motor starter, multi-function timer, and control relays.

The 85-MT5 teaches learners how to troubleshoot motor control circuits under realistic conditions. Circuit faults can be introduced using either the included manual fault insertion system or through the optional Fault Troubleshooting System (890-FTS1), which includes Amatrol’s FaultPro, the industry’s only electronic-fault insertion software.

Amatrol’s Motor Braking Learning System (85-MT5A) adds to the Electric Motor Control Learning System (85-MT5) to expand a learner’s knowledge of the common electric motor braking methods found in industrial, commercial, and residential applications. Braking is essential to motor control when motors must be stopped and restarted multiple times. Common applications include rolling mills, conveyors, and power fans. Learners study industry-relevant skills for three of the most common braking methods: electromagnetic braking, plugging, and DC injection braking. Troubleshooting braking problems under realistic conditions allows learners to experience the challenge and reward that result from applied problem solving.

The motor braking training system includes a DC braking station with power supply, transformer and bridge rectifier mounted to a slide-in panel, inertial load module with flywheel, electromagnetic brake, plugging/anti-plugging switch, student curriculum, and instructor’s guide. This system uses industrial quality components that stand up to frequent use and enable learners to better prepare for what they will encounter on the job.

Pages

-

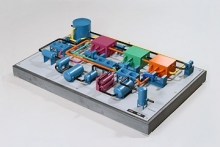

Item Number:295-901DAC's Phillips Cascade Process (LNG) System Model is a detailed and stylized scale model of a single train LNG production/conversion system, designed for training purposes.

-

Item Number:428DAC Worldwide’s Piloting Switch Module (428) is a motor control-related device that compliments and expands the usefulness of related DAC Worldwide motor control training systems by incorporating alternate switch components and other devices into control circuitry as found in industrial systems.

-

Item Number:295-706DAC's Piston Check Valve Cutaway (295-706) is a sectioned valve sample for training in the operation, construction, and maintenance of industrial piston-type check valves.

-

Item Number:205-280DAC Worldwide's Planetary Gear Reducer Cutaway (205-280) is a sectioned industrial, mounted planetary gear reducer for use in classroom and laboratory training relating to mechanical drives. This example has been restored, cutaway, and refinished using durable coatings.

-

Item Number:205-180The Planetary Gear Reducer Dissectible is a sturdy unit mounted on a 7-gauge, formed-steel baseplate with provision for bench-top, workstation, or storage rack mounting.

-

Item Number:284DAC Worldwide’s Plate-Type Heat Exchanger Model (284) depicts a highly-detailed scale model of a common plate-type heat exchanger in a technically-accurate, professionally-crafted design. Based on a common make and model of a heat exchanger, the product is a complete to-scale replication of typical plate-type heat exchangers found in industry.

-

Item Number:PLC HMIRockwell Automation (Allen Bradley) CompactLogix control panel electrical project kit

-

Item Number:PLS 6.150DThe PLS6.150D is a free-standing platform with a materials processing envelope of 32" x 18" x 8.5" or 4,896 in³ that supports dual lasers. As a dual laser platform, the PLS6.150 can support up to two 10.6µm CO2 lasers with a power range of 10 watts to 150 watts. Additionally, it can support a single 9.3µm CO2 of 30, 50 or 75 watts. (if a 9.3µm CO2 laser is installed, only one 10.6µm CO2 of up to 75 watts may be installed at the same time.)

-

Item Number:760CDAC Worldwide’s Pneumatic Component Cutaway Set (760) is a tabletop assortment of industrial pneumatic components that have been modified for classroom use as teaching aids for pneumatic component training.

-

Item Number:295-713DAC Worldwide’s Pneumatic Level Controller Assembly Cutaway (295-713) is a sectioned, highlighted float-operated pneumatic level controller assembly that allows for realistic demonstration and training related to this common level control device used in oil and gas production operations.