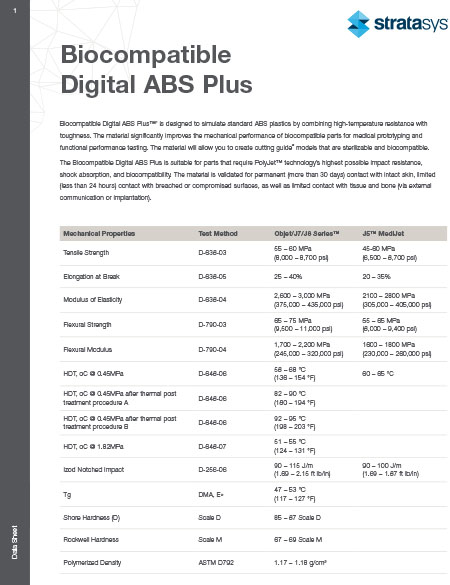

Biocompatible Digital ABS Plus™1 is designed to simulate standard ABS plastics by combining high-temperature resistance with toughness. The material significantly improves the mechanical performance of biocompatible parts for medical prototyping and functional performance testing. The material will allow you to create cutting guide2 models that are sterilizable and biocompatible.

The Biocompatible Digital ABS Plus is suitable for parts that require PolyJet™ technology’s highest possible impact resistance, shock absorption, and biocompatibility. The material is validated for permanent (more than 30 days) contact with intact skin, limited (less than 24 hours) contact with breached or compromised surfaces, as well as limited contact with tissue and bone (via external communication or implantation). /p>

1 Biocompatible Digital ABS Plus is fabricated using MED515 Plus together with MED531

2 With approved 3rd party 510k cleared segmentation software.

3 WSS™150 is not biocompatible.

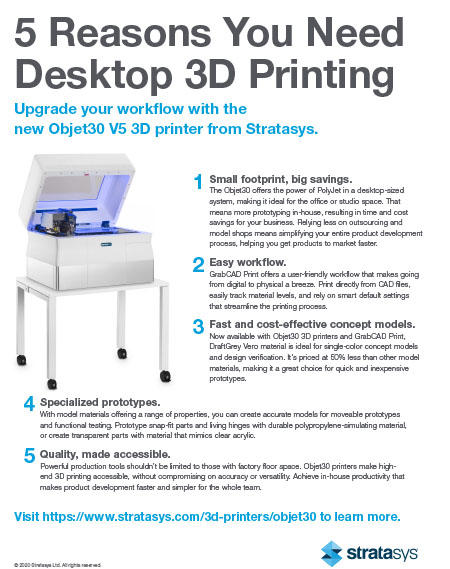

Upgrade your Workflow

With the Objet30 V5 3D printer from Stratasys.

The Objet30 provides accurate and versatile 3D printing - all from your desktop. With excellent print resolution, the Objet30 lets you create single material parts with smooth surfaces, small moving parts, and details like thin walls. The roomy tray size provides versatility for various consumer goods, electronics, medical devices, and more. Thanks to GrabCAD Print, the Objet30 also provides a user-friendly workflow, so you can get printing faster and easily manage print jobs.

Learn five reasons why you need desktop 3D printing.

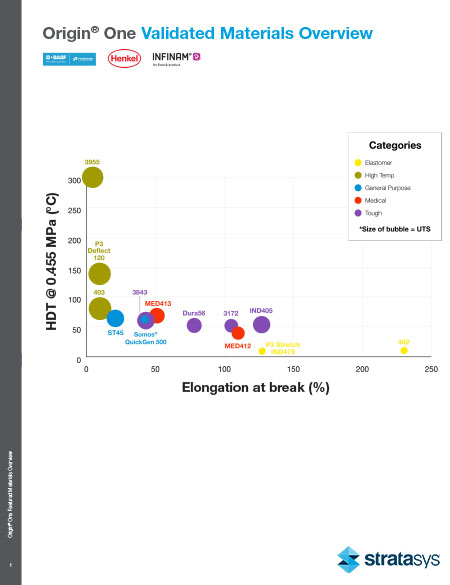

LOCTITE 3D IND402 is a single-component elastomer material with high elongation and high resilience, excellent tensile strength, and high energy return while also not requiring thermal post-processing.

Parts can be printed with various DLP platforms.

This guide should be used to compare Origin-certified materials with each other. Please refer to individual material data sheets for more info.

Resilient high-resolution elastomers for applications requiring excellent tear strength or rebound performance.

Fast printing materials for end-use applications requiring cosmetic surfaces, fine features, and high accuracy.

Materials for application-specific requirements such as flame smoke and toxicity, HDT or mold durability.

Medically certified materials for devices where aesthetics, durability and biocompatibility are critical.

Impact-resistant resins for functional applications that need to perform under stress and high-load conditions.

Additive manufacturing will only penetrate end-use production if and when manufacturers have access to engineering-grade materials that bring the required properties to their applications - at the time of printing and throughout its lifetime.

Somos® materials scientists are putting their industry-proven photopolymers toolbox to work to develop high-performance materials for DLP/LCD technology. The combination of engineering-grade materials with fast DLP technology at lower cost of entry makes 3D printing accessible to companies looking to transition to additive manufacturing.

Choose from application-specific materials that have proven performance and come with industry-standards testing data.