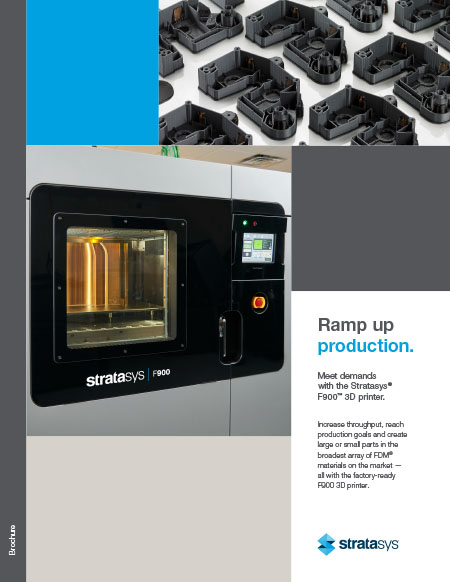

Built for large-scale manufacturing.

Meet demands with the Stratasys® F900™ 3D printer.

Increase throughput, reach production goals, and create large or small parts in the broadest array of FDM® materials on the market — all with the factory-ready F900 3D printer.

Designed and built for size, throughput, precision, and repeatability.

The Stratasys F900™ is the most precise and powerful FDM® system available. With the largest build size of any Fortus® system, the Stratasys F900 is designed to handle the most demanding manufacturing needs. The accuracy, repeatability, and predictability are unmatched, and the control software leverages the system’s hardware to deliver superior throughput and reliability.

The Stratasys F900 uses engineering-grade thermoplastics to build robust production parts, jigs, fixtures, factory tooling, and functional prototypes. Large parts are printed fast with slice heights up to 0.020 inches to help easily meet production demands.

The Stratasys F900 offers a streamlined workflow and easier job monitoring with an internal camera, GrabCAD Print™ software, Insight™, and MTConnect readiness. Data security, including U.S. Department of Defense STIG compliance, is provided by Stratasys ProtectAM™ technology. Standard certifications are included and reduce the workload to qualify 3D printers for a production floor.

How is the Fortus 450mc different?

Create complex geometries

- Create low-volume production parts, high-quality custom tools and functional prototypes

- The large build platform has the capability to meet industrial application needs

- Hands-free soluble support materials reduce labor while aiding in complex designs

- Easy to operate and integrate into your factory floor

Wide range of materials

- The 14 available materials support a variety of applications

- From the stiff strength of carbon fiber to the chemical resistance and ESD performance of Antero™ thermoplastics, there’s a material to meet your needs

Unparalleled consistency and precision

- Parts from the Fortus 450mc have a high degree of dimensional accuracy and precision, shown over months of tests across multiple printers with various builds

- A low variance combined with a high print success rate give you consistent, repeatable results

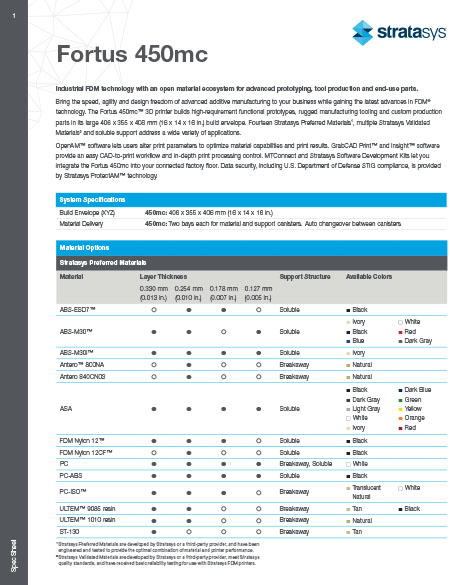

Industrial FDM technology with an open material ecosystem for advanced prototyping, tool production and end-use parts.

Bring the speed, agility, and design freedom of advanced additive manufacturing to your business while gaining the latest advances in FDM® technology. The Fortus 450mc™ 3D printer builds high-requirement functional prototypes, rugged manufacturing tooling, and custom production parts in its large 16 x 14 x 16 in. build envelope. Fourteen Stratasys Preferred Materials, multiple Stratasys Validated Materials, and soluble support address various applications.

OpenAM™ software lets users alter print parameters to optimize material capabilities and print results. GrabCAD Print™ and Insight™ software provide an easy CAD-to-print workflow and in-depth print processing control. MTConnect and Stratasys Software Development Kits let you integrate the Fortus 450mc into your connected factory floor. Data security, including U.S. Department of Defense STIG compliance, is provided by Stratasys ProtectAM™ technology.

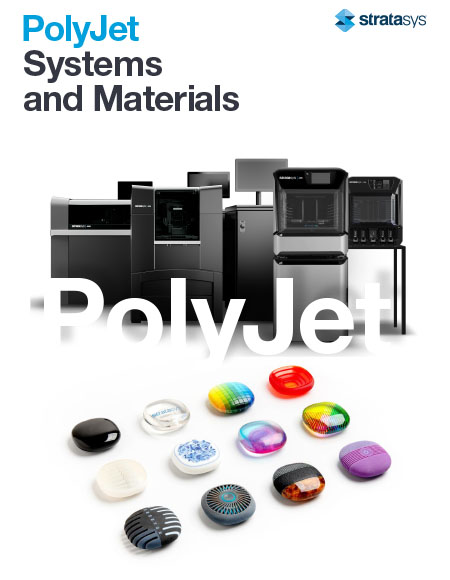

PolyJet™ 3D printers empower designers, engineers, educators, and healthcare professionals to create and problem-solve without the limitations of traditional modeling methods. The power lies with PolyJet technology, curable liquid photopolymers capable of producing very fine layers for smooth surfaces, intricate details, and vivid color.

Stratasys® PolyJet technology helps bring to life ideas in virtually any spectrum of colors, and any combination of translucency, opacity, rigidity, and elasticity, while simulating several desired materials and finishes.

The versatility of PolyJet technology is based on a wide range of available material properties and a suite of 3D printers to suit varied budgets and applications. No matter the industry, PolyJet technology provides the power to hone ideas quickly and accurately.

- Help designers save 50 percent of their time. Product designers and developers can create realistic prototypes and models with full-color elements, labels, and true-to-life textures in one operation, to gain focus-group feedback before committing to full production.

- Full-color, flexible materials enable lifelike anatomical models for physician training and pre-surgical planning that lower operating room costs and improve patient outcomes.

- Educators can empower students to design, test, and discover in days, not weeks.

- Dental labs can increase productivity by making multiple models and try-ins in a single print operation to boost production capacity and fuel growth.

PolyJet technology enables you to create parts and prototypes with the best surface quality, finest details and widest range of material properties available. Eliminate design barriers and improve communication and collaboration while creating realistic prototypes to better evaluate future products; ergonomic tooling to streamline production; or specialized items like biocompatible surgical guides, among many applications.

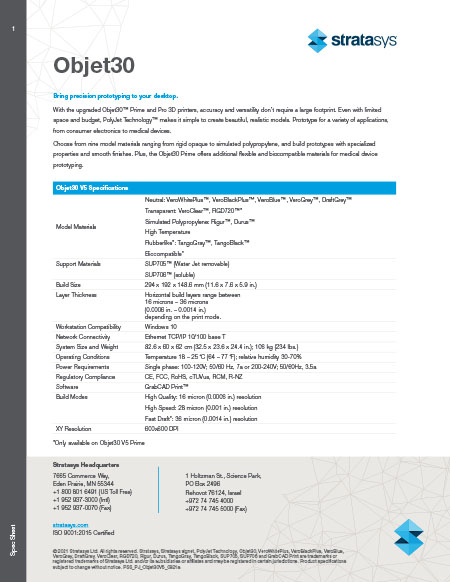

Bring precision prototyping to your desktop.

With the upgraded Objet30™ Prime and Pro 3D printers, accuracy and versatility don’t require a large footprint. Even with limited space and budget, PolyJet Technology™ makes creating beautiful, realistic models simple. Prototype for a variety of applications, from consumer electronics to medical devices.

Choose from nine model materials ranging from rigid opaque to simulated polypropylene, and build prototypes with specialized properties and smooth finishes. The Objet30 Prime offers additional flexible and biocompatible materials for medical device prototyping.

Pages

-

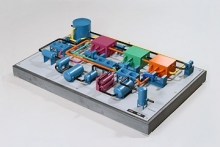

Item Number:295-901DAC's Phillips Cascade Process (LNG) System Model is a detailed and stylized scale model of a single train LNG production/conversion system, designed for training purposes.

-

Item Number:428DAC Worldwide’s Piloting Switch Module (428) is a motor control-related device that compliments and expands the usefulness of related DAC Worldwide motor control training systems by incorporating alternate switch components and other devices into control circuitry as found in industrial systems.

-

Item Number:295-706DAC's Piston Check Valve Cutaway (295-706) is a sectioned valve sample for training in the operation, construction, and maintenance of industrial piston-type check valves.

-

Item Number:205-280DAC Worldwide's Planetary Gear Reducer Cutaway (205-280) is a sectioned industrial, mounted planetary gear reducer for use in classroom and laboratory training relating to mechanical drives. This example has been restored, cutaway, and refinished using durable coatings.

-

Item Number:205-180The Planetary Gear Reducer Dissectible is a sturdy unit mounted on a 7-gauge, formed-steel baseplate with provision for bench-top, workstation, or storage rack mounting.

-

Item Number:284DAC Worldwide’s Plate-Type Heat Exchanger Model (284) depicts a highly-detailed scale model of a common plate-type heat exchanger in a technically-accurate, professionally-crafted design. Based on a common make and model of a heat exchanger, the product is a complete to-scale replication of typical plate-type heat exchangers found in industry.

-

Item Number:PLC HMIRockwell Automation (Allen Bradley) CompactLogix control panel electrical project kit

-

Item Number:PLS 6.150DThe PLS6.150D is a free-standing platform with a materials processing envelope of 32" x 18" x 8.5" or 4,896 in³ that supports dual lasers. As a dual laser platform, the PLS6.150 can support up to two 10.6µm CO2 lasers with a power range of 10 watts to 150 watts. Additionally, it can support a single 9.3µm CO2 of 30, 50 or 75 watts. (if a 9.3µm CO2 laser is installed, only one 10.6µm CO2 of up to 75 watts may be installed at the same time.)

-

Item Number:760CDAC Worldwide’s Pneumatic Component Cutaway Set (760) is a tabletop assortment of industrial pneumatic components that have been modified for classroom use as teaching aids for pneumatic component training.

-

Item Number:295-713DAC Worldwide’s Pneumatic Level Controller Assembly Cutaway (295-713) is a sectioned, highlighted float-operated pneumatic level controller assembly that allows for realistic demonstration and training related to this common level control device used in oil and gas production operations.