THE NETHERLANDS - July 14, 2016: Carnival Corporation's new world-class Center for Simulator and Maritime Training (CSMART) was officially opened in Almere, Netherlands today. The CSMART is the largest facility in terms of training capacity and utilises the most innovative technology solutions from Transas.

THE NETHERLANDS - July 14, 2016: Carnival Corporation's new world-class Center for Simulator and Maritime Training (CSMART) was officially opened in Almere, Netherlands today. The CSMART is the largest facility in terms of training capacity and utilises the most innovative technology solutions from Transas.

The Transas Integrated Full Mission Simulation Academy Solution implemented at the CSMART is a significant innovation that moves the capability of the most complex challenge to maritime safety forward.

Carnival recognised that a step-change was required in the way seafarers are trained to improve safety at sea. The interaction of human factors on board cruise vessels are some of the most complex in the maritime industry. Crews empowered with a solid foundation of generic core competencies ensure significantly better safety outcomes than those that rely heavily on established roles and procedures.

As a result of almost two-years of intensive R&D investment, the new training environment concept has now become a reality at the CSMART facility.

The CSMART facility houses navigational and engine room simulators in various configurations from classroom stations up to part-task and full mission solutions, interlinked to provide training and assessment for the entire crew.

Through cooperation with Dell, Transas reduced the number of physical machines by 77 percent from 650 to 150 and cut energy consumption by 30 percent compared to a traditional deployment by the virtualisation of simulation tasks into nVidia Grid System.

Full interswitching capabilities where any task can be available on any screen within the Simulator (Blackbox IP-matrix) allow for a zero percent downtime which was one of the key requirements due to a to high volume throughput of seafarers with defined limited training windows.

CCTV camera technology, similar to the one used at the ESA Space Centre, observes and records everything on the bridges and in the engine room to allow full picture team training. Access is available to any task on any screen within the simulator while the CCTV provides professional broadcast, AV control, recording and archiving system with full synchronisation of all workstations, cameras and audio.

To ensure realistic team situational training for engine room and machinery functions, Transas has implemented high tech 'gamification' technology with 3D Engine compartments walk-through including usage of avatars controlled via large touchscreens or gaming controller. The trainee moves avatar through the machinery compartments and can act as a team with other trainees in case of emergency procedures.

Transas CEO Frank Coles comments: «The CSMART project is an important milestone in the Transas history. We are proud of what has been achieved in such a short time through our close work with the Carnival Corporation, the CSMART team and our project partners. By applying technological advancements never before utilised within the maritime industry, Transas have created a multi-simulator integrated training that delivers an immersive real world situational environment in which multiple crew members can operate and interact simultaneously, as if on a real vessel. This is the standard by which all training should be measured».

Read full article here.

Innovation and Technology Leadership

Universal Laser Systems understands the importance of implementing innovative technology into your school. The demand for students to be “technically-savvy” and “digitally literate” has multiplied in just a few years. You want to allow your students to work with the latest technology to prepare them for their futures.

The laser systems they offer can cut through and precisely engrave many materials. Not only will your students gain essential skills, but they will also be able to see their designs and ideas come to life.

Visit Universal Laser Systems to learn more.

*Desktop units are shown on optional air cleaner cart.

Our medical training solutions encompass a comprehensive range of tools to enhance learning and skill development in patient care. We offer cutting-edge medical simulators and K-9 Simulators from TacMed, providing realistic and immersive training experiences for healthcare professionals and first responders. These simulators are designed to simulate real-world scenarios, allowing users to practice critical procedures and decision-making skills in a safe and controlled environment.

In addition to our physical simulators, we also offer virtual reality training solutions through VRNA. Our VRNA CNA and EMS modules are specifically tailored to supplement traditional lab instruction. By leveraging fully immersive VR experiences, VRNA helps instructors optimize their teaching efficiency, reduce split attention during small group activities, and keep students actively engaged in lab content. This approach empowers learners with independent practice opportunities, enabling them to hone their patient care skills with confidence in a zero-risk setting.

Universal Laser Systems (ULS) takes pride in its laser engraving systems' innovative technologies and modular components. With over a million laser system configurations, users can laser engrave on numerous materials with high precision and speed.

ULS laser engraving systems utilize a precise, non-contact process that upholds the integrity of the material even if directed onto small areas.

Laser Systems with Flexibility

Users of ULS laser engraving systems enjoy how easy it is to operate and customize for their specific business needs. With processing areas ranging from 16" x 12" to 48" x 24" and options for single or dual lasers—on top of a host of add-on features and patented technologies—you will have a laser platform that can adapt to your unique requirements.

Universal Laser Systems offers laser sources that range in power from 10 watts to 150 watts and are available in three wavelengths: 10.6μ, 9.3μ, 1.06μ.

Laser Engraving, Cutting, and Marking with ULS Laser Systems

One of the most impressive capabilities of ULS laser machines is the capacity to execute two or three laser processes with the same system—whether laser engraving, laser cutting, and/or laser marking—eliminating the need for multiple laser platforms. Users can enhance business productivity, increase their return on future investments, and take advantage of ULS' patented technologies with a singular laser system.

Students in the University of West Florida College of Health now have the opportunity to gain an in-depth understanding of the human body through the use of synthetic cadavers. The cadavers are part of the newly developed Applied Anatomy and Physiology Laboratory, housed within the Department of Exercise Science and Community Health.

The state-of-the-art lab was developed to impact students in all programs under the College of Health as they study individual and overlapping aspects of human health. Exercise science and athletic training students are able to use the SynDaver Anatomy Models to gain a spatial understanding of musculoskeletal interactions and neural and vascular systems while nursing students are afforded a more in-depth experience for intramuscular injections and intravenous line placements.

Students in the Doctor of Physical Therapy program are also utilizing the SynDavers for hands-on practice in helping patients through specific muscle movement exercises. Students from the public health, health sciences, medical laboratory sciences and psychology programs will also access them for discipline-specific, hands-on experiences.

“The SynDavers allow students to physically interact with the human body,” said Dr. Eric Greska, assistant professor in the Department of Exercise Science and Community Health. “With these experiences, our students are able to visualize the structures within the body as they interact with patients on the surface level.”

Students in the Doctor of Physical Therapy Program, a partnership between UWF and the University of South Florida, are utilizing the SynDavers to study anatomy focused on human movement, said Dr. Steve Ambler, associate professor in the USF School of Physical Therapy and Rehabilitation Sciences and coordinating faculty member for the UWF/USF DPT Partnership. The lab’s technology also enables them to broadcast their lessons to USF, which Ambler said broadens the impact and allows even more students to benefit from the hands-on learning experience.

“We can put the SynDavers in the context of different movements so that students can understand how changes in movement impact anatomy,” Ambler said. “Students are also gaining valuable experience as peer teachers for undergraduates in various programs under the College of Health. All health-related disciplines are intertwined. I think it’s incredibly beneficial that the new Applied Anatomy and Physiology Laboratory and its technology are creating an inter-professional learning environment for all students in the UWF College of Health.”

The SynDaver is an education-grade synthetic human cadaver, complete with all bones, joints, muscles, organs and tendons in normal human anatomy and made from materials that mimic the mechanical, thermal and physicochemical properties of live tissue. Major nervous system and vascular components are also included.

The synthetic cadaver is an ideal alternative to human cadavers, allowing students in the College of Health to become familiar with the look and feel of a live human body without specialized facilities, risk of exposure to biohazards or compromising a live patient. UWF purchased three cadavers through the UWF Systemic Technology grant, which is funded by student technology fees.

Synthetic cadavers like these are also being used at institutions such as the University of Florida, Columbia University, Harvard University, the Massachusetts Institute of Technology and Oxford University in the United Kingdom.

http://news.uwf.edu/uwf-college-of-health-adds-synthetic-cadavers-to-sta...

View Collaborative Robots from FANUC – The world’s leader in industrial robotics and automation. Developed out of the spirit of collaboration, these are the first industrial robot able to work alongside of students without the need for fencing, with the ability to lift and move heavy objects up to 35 kg. These robots stop on contact and restart with the simple push of a button.

These robots are green because... they are different!

In contrast to yellow FANUC robots, the green color lets everyone know the robots are designed to work side by side with humans, and don't require a fence! That frees up a lot of valuable floor space and cuts costs. They have highly sensitive contact sensing technology and soft outer skin, so you don't have to worry about bumping them. It will gently stop if they come into contact with something while working, It's ISO 10218-1:2011 safety certification is proof that it can share a workspace.

FANUC’s new CR-35iA is the world’s first collaborative robot with a payload capacity of up to 35 kg. Fenceless, it opens a whole new world of possibilities. Working safely side by side with human operators, it is space as well as cost saving. And because inside it’s like any other FANUC robot, it operates like all FANUC robots.

WASHINGTON (Gray DC) -- Virtual reality, high tech security systems. All things students are engaging in and learning at the Arlington Career Center.

"When I was a student this class changed my life," Wilmer Castro said.

Wilmer Castro took a collision repair class here, now he teaches it.

"This class led me to owning a small business, actually two of them, it helped me travel through South America, I travelled through different countries in South America, doing just what I was teaching the students how to do today," Castro added.

Over 20 different career technical education, or CTE programs, are currently being offered through the Arlington Public School System. The goal is to get students fully prepared to enter the real world.

"When I first started here it was kind of uncommon for a student to walk out of here with a certification but these students can walk out with a certification that they can actually work in industry after they graduate," Kris Martini, Director of Career Technical and Adult Education with Arlington Public Schools said.

Some of these programs are currently supported by federal funds and a bill moving through Congress would help strengthen that support.

"It's interesting when you look at workforce data how kids are starting to form some initial decisions maybe earlier than what some of us did in the past," Congressman Glenn Thompson (R-PA-5) said.

Pennsylvania Congressman Glenn Thompson helped introduce the ‘Strengthening Career and Technical Education for the 21st Century Act’. The bill provides builds on a law passed in the 1980's, which increases federal financial support to state and local CTE programs and adds reforms that reflect the challenges of our time.

"They’re fretting they’re worrying about how do they make ends meet well this is an opportunity to get access to high quality career and technical education training, be able to find that, not just to get a job but to get a better job than the one they had," he added.

For Castro, paying it forward is part of the job, and this legislation would help to him continue to do that.

"We can't all sit behind a desk. Sometime I feel that we look badly upon this work, but that's what builds the nation I feel like," he said. "Once you enjoy what you're doing you don’t care about your job." I think if we find out passion we can always figure out what career best fits us," Castro added.

The bill passed in the House but not in the Senate. Thompson said he is hopeful he’ll see action by the end of the year.

TCT Magazine

GE Additive have today announced a $10 million investment across five years in two educational programs aimed at developing future talent in additive manufacturing.

The additive specialists believe enabling educational institutions to provide access to 3D printers will help accelerate the adoption of additive manufacturing worldwide.

Of the two programmed, one is designed for primary and secondary schools, while the other is designed for colleges and universities. GE will invest $2 million over two years to subsidise up to 2,000 desktop polymer printers for primary and secondary schools, districts and systems around the world. Priority will be given to institutions serving ages 8-16 with a strong commitment to Science, Technology, Engineering and Math (STEM) education.

The other $8 million will be spent over five years to subsidies up to 50 metal additive machines to colleges and universities around the world. Priority will be given to institutions with curriculum and/or research underway in the area of additive manufacturing.

“We want to build an ecosystem that drives additive manufacturing across multiple industries,” said Mohammad Ehteshami, Vice President of GE Additive. “GE is committed to this space for the long-term. A new world is coming and we want future generations to have exposure to it from an early age.”

GE has been actively supporting education for more than a century. Its efforts tend to focus on areas that have the greatest impact and can improve outcomes for students. In the US alone, GE has invested more than $225 million and thousands of hours to support public education.

View Stratasys 3D Printers

Learn how Anchorage School District's portable career exploration strategy paves the way for new certification programs with Simlog's Personal Simulators.

Pages

-

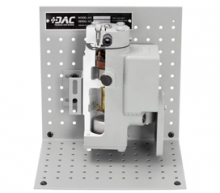

Item Number:773-050DAC Worldwide's Hydraulic Pressure Gauge Cutaway (773-050) is a Bourdon tube-type pressure widely used in industrial liquid and gas processes to monitor and document system pressures. The full-size, fully-detailed example gives learners a first-hand view into a component that is found in various applications worldwide.

-

Item Number:773-217DAC Worldwide's Hydraulic Pressure Relief Valve Cutaway, Balanced Piston-Type (773-217) is a sectioned hydraulic, automatically triggered relief valve example with a two-stage balanced piston design, which incorporates a commonly-encountered valve type manufactured by an industry leader. T

-

Item Number:773-213DAC Worldwide's Hydraulic Sequence Valve Cutaway (773-213) is a sectioned hydraulic sequence valve example with a two-stage balanced piston design, which incorporates a commonly-encountered valve type manufactured by an industry leader.

-

Item Number:273-840DAC Worldwide’s I/P Transducer Cutaway (273-840) is a detailed I/P converter cutaway that depicts a common current-to-pressure transducer used within industrial process control systems. This common piece of pneumatic control hardware is found in manufacturing facilities, petrochemical plants, refineries, and other similar industrial, commercial, and oil and gas applications.

-

Amatrol's IGNITE: Mastering Manufacturing program teaches Industrial Internet of things (IIoT) & Industry 4.0 skills required for today's manufacturing careers.

-

Item Number:ILS12.150DThe ILS12.150D is a free-standing platform with a materials processing envelope of 48" x 24" x 12" or 13,824 in³. The dual laser platform supports a power range of 10 to 150 watts (up to 75 watts with one 10.6µm CO2 laser; up to 150 watts with a second 10.6µm CO2 laser). The ILS12.150D also supports a single 9.3µm laser at 30, 50 or 75 watts (If a 9.3µm CO2 laser is installed, the maximum 10.6µm laser is 75 watts).

-

Item Number:ILS12.75The ILS12.75 is a free-standing platform with a materials processing envelope of 48" x 24" x 12" or 13,824 in³. The single laser platform supports either one 10.6µm CO2 laser (10 to 75 watts) or one 9.3µm CO2 laser (30, 50 or 75 watts).

-

Item Number:ILS9.150DThe ILS9.150D is a free-standing platform with a materials processing envelope of 36” x 24” x 12” or 10,368 in³. The dual laser platform supports a power range of 10 to 150 watts (up to 75 watts with one 10.6µm CO2 laser; up to 150 watts with a second 10.6µm CO2 laser).

-

Item Number:ILS9.75The ILS9.75 is a free-standing platform with a materials processing envelope of 36” x 24” x 12” or 10,368 in³. The single laser platform supports either one 10.6µm CO2 laser (10 to 75 watts) or one 9.3µm CO2 laser (30, 50, or 75 watts).

-

Item Number:iLSEach base can hold up to 12 modules to accommodate multiple applications and/or multiple students while still fitting through a standard doorway.